查看完整案例

收藏

下载

Appreciation towards Jinjing Yu for providing the following description:

英国建筑联盟学院

Architectural Association, Emergent Technologies & Design,Thesis

研究团队:俞金晶,马也旻,Cagla Gurbay, Prajish Vinayak

建筑的首要目的之一是给人维持一个舒适环境的庇护所。然而,持续的自然和人为因素的变化对人的舒适度产生了互动式响应的需求。直到今天使用空调系统来调节室内空间舒适度是比较普遍的方式,但本论文研究根据流体动力学和自然通风率计算的引导方式和技术提出以风引起的自然通风作为更好的选择在多个室内微环境中响应人的使用流动变化。提出的论点是通过封闭空间的形态演变和混合形态的构建系统一起实现一个整体性能驱动的建筑。

Architecture’s primary purpose is sheltering while maintaining human comfort within surrounding circumstances. In the case of human comfort, continuous change of natural and man-made parameters at different scales creates the necessity of dynamic response. Being designed for generating solutions, air conditioning systems controlling isolated inner spaces were a significant method until today. In light of conducted methods and techniques such as optimization through computational fluid dynamics, natural ventilation rate calculations, this dissertation suggests wind-induced cross ventilation as better alternative in manipulating interior microclimates in response to occupancy fluxes. The argument presented here investigates an envelope generated through evolutionary form-finding.and is overlaid with an hybrid dynamic component system which together delivers a holistic performance driven architecture.

整个系统的设计是基于自然通风能平衡人的舒适度的基础上展开的.主要运用遗传算法,有限元结构分析和适应性材料测试等技术,分别解决建筑形态,曲面细分和动态感应.自然通风的原理方法及其数学公式作为风引起的对流通风的基本概念被运用到设计过程中.流体计算动力学(CFD)是本研究的基础, 遗传算法即形态计算演变的过程是根据CFD的计算结果逐步优化的, 其中研究的类型是定量的;有限元结构分析被用于形态几何物理分析和受空气动力限制的组件和整体结构性能设计的过程中;计算控制系统中包括接受湿度,温度和风压强感应器的数据和计算分析数据的代码,控制材料的性质从而满足空间质量变化的动态需求. 在材料研究中,记忆合金和木材的合成方法为整个系统提供了应用可行性.

In specific climate conditions, human comfort can be achieved by natural ventilation through utilizing envelope as a responsive interface. The methodology for achieving this goal aimed to get benefit from current knowledge on aerodynamics and development of a dynamic component system works with these principles to enhance the human comfort. The type of research is quantitative. The project sought to unite the architectural, environmental and structural performance of the design through the introduced methodology. Natural ventilation principles method enhanced the knowledge on the basic notions and concepts of wind-induced cross ventilation. The mathematical formulations of these principles were noted down to be used in generation and evaluation of the design development steps. Computational Fluid Dynamics (CFD) method formed the basis of the project. This method was including the physical air flow imitation through computation and was utilized when simulation of air behaviour needed. Evolutionary computation drew upon the strategies derived from CFD trends. Mimic the emergent aspect of nature through computational process was the underlying methodology in form-finding process of the design. Finite Element Analysis is based on computational process of unitizing a domain system with regard to solve complex problems. The method calibrated global geometry, physical and aerodynamic restrictions of component and global structural performance in design experiments. Computational Control System consisted of the sensory tools and computational rule-based system. The method efforted to control material phenomena dynamically for heterogenous instant needs of different space qualities. Hybrid material system method included the possible application of plywood and SMA wires.

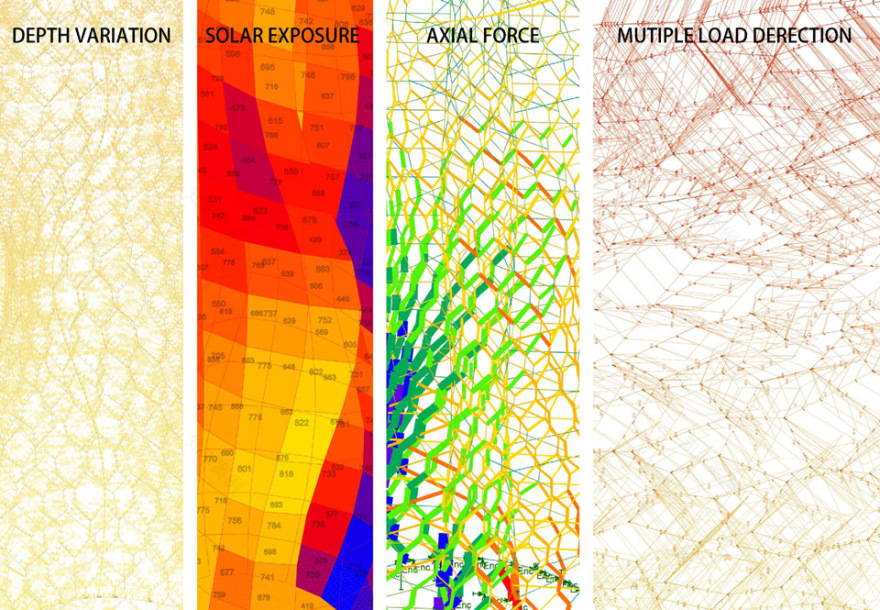

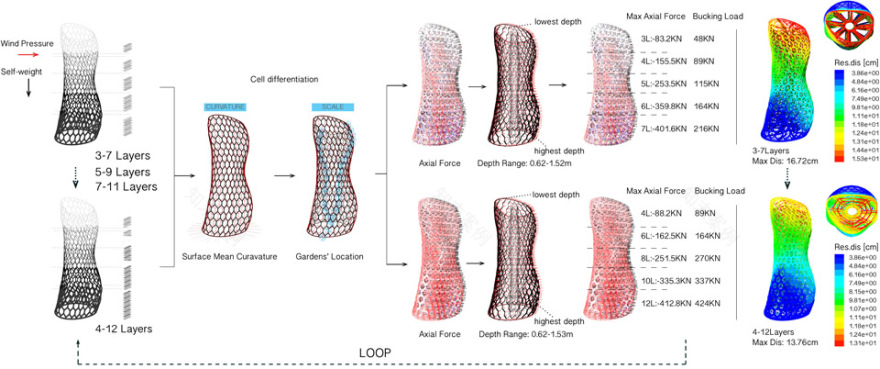

建筑形态进化_遗传算法:

在自然界中,自下而上的涌现现象通常是形式出现的原始策略。压力诱导自然通风作为遗传算法的准则,用于结合涌现和行为演化。以一个简单的形态作为开始,根据预先确定的信息开始发育演化。在我们的案例中被定义为三个不同的空间形态,根据压力的不同,组织空间结合方式以及形态的逐步演化的过程为进化过程.系统的复杂性不单来自单个组件的复杂性同时包括复杂的规则设定.在生物学中,这种规则被命名为基因组的行为,在内部和外部因素共同作用下,进化的基因组是通过突变和自然选择以实现更高的效率和更好的表现。

将表面上的控制点视作基因,控制点可以在一定的三维空间内移动以产生不同的形态变化。通过原始基因和突变基因的繁殖,产生了7个种群,将每个种群通过计算机流体分析(CFD)对通风流速和湍流强度进行性能评估。第一个衡量标准是根据单向为6m/s的风在表面上形成高压强差以增强室内的通风流速和准确的开口位置的设置;第二个衡量标准是根据建筑形式的外部形态尽量减少两侧和背侧湍流动能(TKE)来确保流出的流体不被影响。在场地和功能的定义下,考虑空间体积,基座面积和高度限制的情况下,有三个高效率的形式作为潜在的最终形态被选出。

EVOLUTIONARY FORM-FINDING

The suitable bottom-up approach of emergence phenomena in natural systems is the driving strategy for the form-finding method of the thesis. Evolutionary computation is the method for combining the aspects of emergence and its performative evaluation which in this case in terms of pressure induced natural ventilation. Emergence begins with a simple cell. According to a pre-determined information, the cell development emerges. In our case, the cell is defined as the set organisation of three volumes. The initial cell was developed by the steps of angularity of the form and orientation of organisation of the three volumes together for pressure difference efficiency. Complexity of the system is derived not from complexity of the components but the complexity of rule sets. This rule set is named as genome, and the operations are the genes in biology. The evolution of the genomes is through the mutations and natural selection that are happened for achieving higher efficiency for specific external and internal factors. The concept is set the base of computational computation. Degradation of basic biological evolution components; genotype (operations) and phenotype (outputs) enables computing both the generation process and evaluation of the performance of the forms.

The genes used in generating populations was editing operation of the control points of initial form and morphing the surface. Five populations were created through cross breeding the genes with insertion of new genes and also mutating the original genes. Each form generated was inputted into a Computational fluid dynamics (CFD) software to evaluate its performance in ventilation flow rate and turbulence intensity. The evaluation criteria was aiming to achieve higher pressure differential in accordance with an unidirectional wind of 6 m/s as to increase the flow rates inside the volumes when openings were placed on the surface. The second fitness criteria was to minimize the turbulent kinetic energy (TKE) on the sides and leeward side of the form to make the outflow of air in the outlets to not be disrupted by the eddie turbulences formed due to shape of the external form. As a result three high ranking performative forms were shortlisted as potential candidate forms for being selected with different conditions of specific interest or as per plinth area or volume requirements defined by site or program.

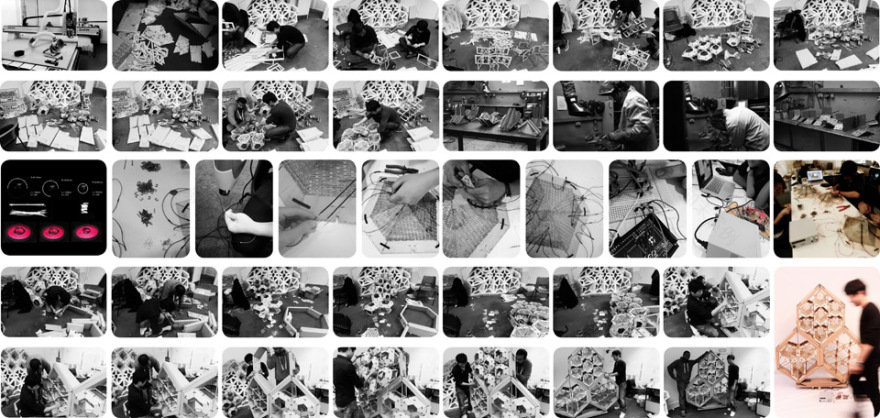

复合材料的组件特性:

组件动态部分的概念来自有重叠区域的花瓣,重叠区域可以减小由风引起的振动。复合材料组件动态的“花瓣”为被切割图案并可弯曲的胶合板,和两组包裹有绝缘套管的记忆合金,分别控制组件开口的打开和关闭,并连接到低电压电源。同时用绝缘和软性的薄硅胶来封住胶合板层的开口图案,将记忆合金夹在胶合板和硅胶中间。

15cm的形状记忆合金在500至800度的热处理下得到具有1/2圈, 3/4圈和整圈曲率的初始形态 。此外,根据杨氏模量的物理方程,促使变形的应力与弯曲曲率的胶合板长度变化是成正比的。同时截面积的大小取决于切割图案的密度及厚度除以胶合板的原始长度。通过进行不同的切割模式试验,预测在现实情况下,想要实现弯曲形状需要约直径为0.8 mm的4条形状记忆合金串联,并与6毫米的胶合板结合。

MATERIALITY OF THE COMPONENT SYSTEM

The dynamic part of the component was derived from the concept of flower petals which have an overlapping area that could be used to prevent the vibration caused by the wind. The composite part of the dynamic “petals” consisted of a plywood layer which was with flexing cut pattern. Two sets of shape memory alloy wires that respectively control the opening and closure of the petals was wrapped with the insulation sleeves. The wires were connected to the low voltage power supply and attached to the plywood layers through a thin silicon patch which blocked the opening areas of the patterns while insulating the heat generated by the electric.

The 150 mm shape memory alloy was heat treated under 500-800 degree to get an initial shape of curvatures of half circle, a 3/4 circle and a whole circle [Figure 8]. Moreover, according to the physical equation, the force that makes the plywood to deform equals the change in length of the plywood which is determined by the bending curvature times the Young’s Modulus. It was determined by the density of the cut pattern times the cross section area. The cross section area was determined by the thickness of the plywood divided by the original length. Through the different cut pattern, more curved shape was achieved and it was predicted that about 16 pieces of shape memory alloy with 0.8 mm diameter made the 6 mm plywood to bend to the desired curved shape under real circumstances.

通过组件对风速控制来实现人体舒适度的需求。根据计算流体动力学实验设置和测试来确定组件的尺寸范围。合适的风速是从外侧的6m/s减小为2m/s。此外,为获得更高效率的空气流量计算,通过的开口应该是单向的。最初对组件的剖面进行了测试,同时组件的最大尺寸由于双向气流的在一定程度上的影响也被最大可能性的测试。只要保持进风口面积和出风口面积在1:3的关系,就可以将6m/s的风速减为2m/s,同时构件的边界和深度不受风速变化影响.

WIND PERFORMANCE OF THE COMPONENT SYSTEM

The wind speed control for human comfort was intended to achieve by component. A set of computational fluid dynamics experiment was done to set the domain for component size.The fitness was wind speed at outlet decreasing from 6 m/s to 2 m/s. In addition, for efficient air flow calculation, the jet through openings should be unidirectional. The upper limit in size of the component was also restricted to some extend due to bidirectional airflow possibility that large openings create. Initial studies began with section of components. The case of outlet being bigger than the inlet cross section area supply better results of decrease in wind speed to 2 m/s.

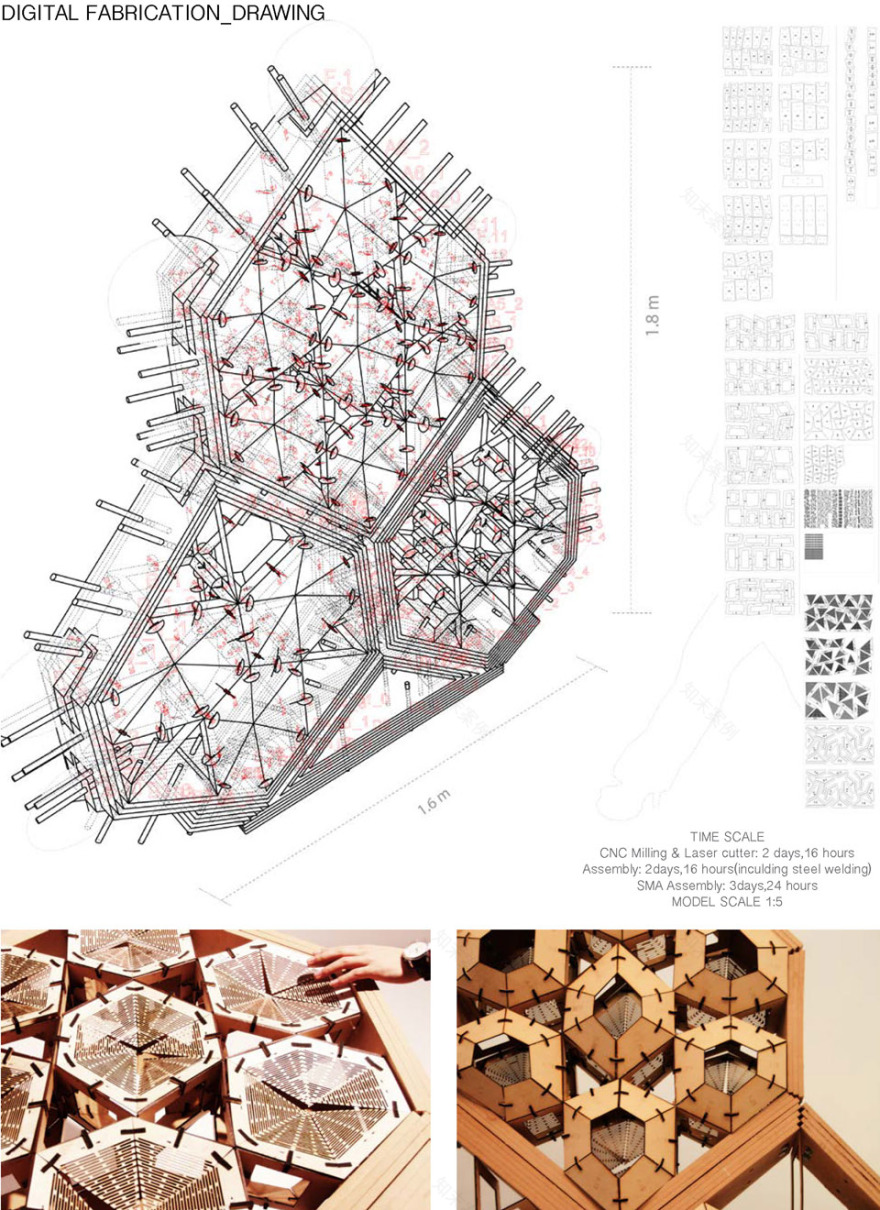

设计实践应用

在对人体舒适度需求以及材料的研究之后,选择了巴西的彼得罗利纳进行了不同的建筑尺度设计应用测试,亭子尺度和中高层尺度。80m高度的中高层设计中有办公,居住,商业和娱乐等公共空间等功能,同时通过有效内部空间组织,根据不同的功能将不同组件形态选择性的运用到整个建筑表皮的不同位置,以通过自然通风实现每层功能不同的微环境需要。

整个建筑的建造方式可以通过先进的电脑数字控制完成的,每一个木片的尺寸和节点的角度都不同,因此在电脑中对木片进行分类和数据编辑,通过CNC Milling 和Robot精确的切割后,可按照编号迅速的进行装配。最终选取了建筑的一部分按照1:5的比例来建造,包括238片不同尺寸的木片和415个不同角度的节点进行CNC切割。总计2天CNC切割,2天装配以及2天记忆合金装配。按照这种建造方式,预计整个建筑可在一年内建造完毕。

COMPUTATIONAL CONTROL SYSTEM

The computational control system made the adaptive capacity of the system intelligent in terms of decision- making over the physical principles of natural ventilation. The capacity of multiple stimuli sense and evaluation through fuzzy logic enhance the reaction of the dynamic component system [Figure 10].

The required amount of openings were located in maximum positive pressure (inlet) and negative pressure (outlet) zones. By temperature and humidity sensors, the heterogeneous demand of microclimatic values are set. The system was sophisticated by the selection flexibility of openings by pressure sensors on them. If the level of humidity or temperature did not returned to the comfortable range after 300 seconds, the cluster of petals with the next highest wind pressure level will be opened until the inside environment gets back to the desired the state. Reversely, the cluster of petals will be closed one by one following the same logic if the real environment level is below the desired range. The central processor of the system is an Arduino Uno board which works under a 5V voltage. The processor board will read the change of electric potential every 5 seconds and turn on and off the actuation circuit accordingly. A transistor will also be used in the system due to the high voltage requirement for the shape memory alloy clusters.

In general, the current needed for petals to actuate is 3-4 ampere will the actuation time will be 10-15 seconds. For each component, 6 pieces of 10 Ohm wire is needed while ten component will be actuated at the same time for a cluster. According to the energy consumption function, energy consumed equals the current square times the resistor’s value times time. In this case, around 60,000 joules will be spend during each actuation for the whole system.

客服

消息

收藏

下载

最近