查看完整案例

收藏

下载

翻译

Architects:blsk. studio

Area :189 m²

Year :2020

Photographs :Maciej Spiess

Manufacturers : Ruukki, Schco, HANTVERKARPOOLEN, ISOCELL, PraefaRuukki

Structural Engineers :Figura Team

MEP & HVAC : Grzegorz Krukowski

Designer Of Water And Sewage : Piotr Simka

Electrical & Lightning Designer : Piotr Świerk

Lead Architect & Interior Designer : Mateusz Skalski

Design Team : Paulina Skalska, Mariola Polimirska Mysiak, Sonia Kwiatkowska

Interior Design Team : Agata Pierożyńska, Sonia Kwiatkowska

Visualisations : Michał Laskowski

Usable Area : 189 m2

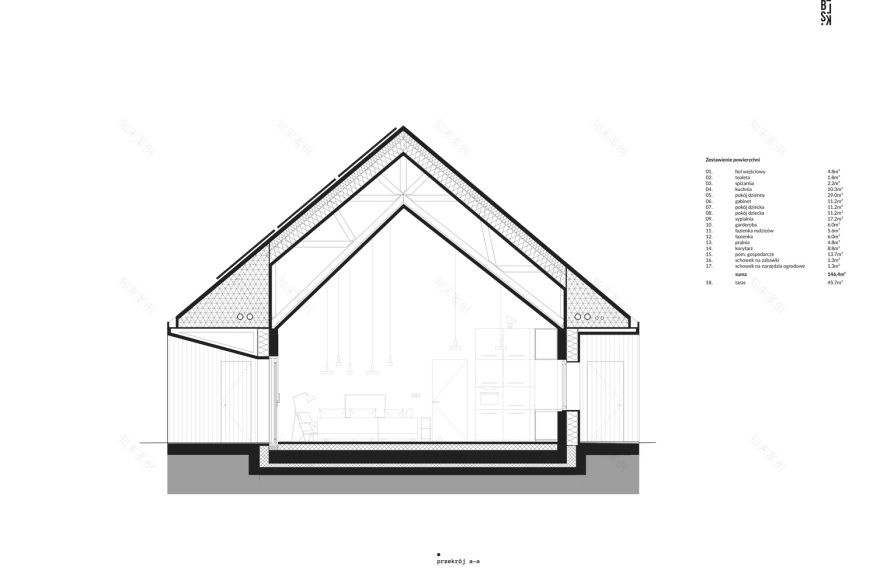

Total Surface : 146 m²

Volume : 1258 m3

City : Gliwice

Country : Poland

From the first conversations with customers sml. house was supposed to be pragmatism and care for the natural environment. Common sense in the selection of materials, keeping the functional program in check, zoning the rooms, a compact body and individual formal and technological solutions meet these original assumptions.

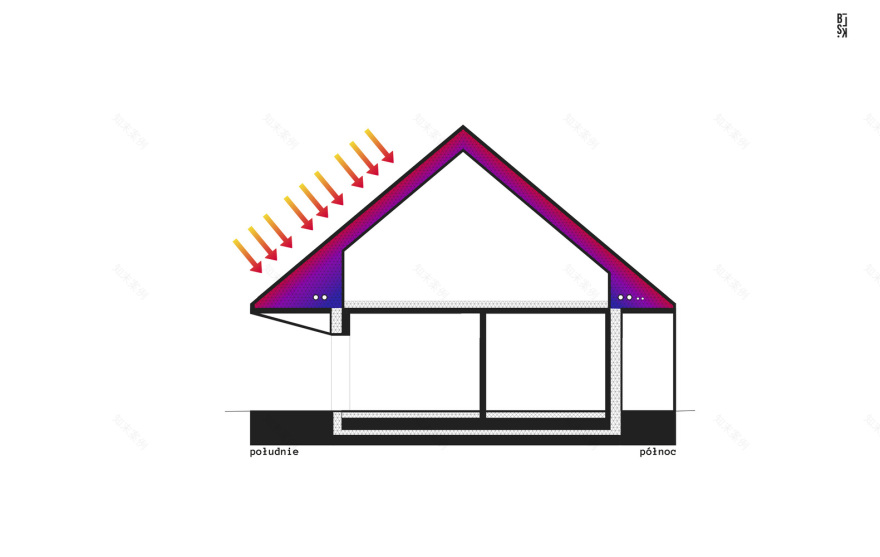

Shape. By maintaining consistency in the functional system and rational formal decisions, it was possible to reduce the demand for the total usable energy of the house to 40.79 kWh/m2 per year. Due to the need to maintain good parameters insulating partitions, all dark rooms have been located on the northern side. From the southern side, there are rooms for longer stays: a living room, children's rooms, a bedroom, and a study. They all have large, terrace sliding doors giving the possibility to exit from each room to a shared terrace.

The building is located adjacent to arable fields and on the southern side, in the longer term, adjacent to the forest. In order to enjoy the beautiful landscape, we tried to reconcile our introduction of large glazing on the south side with the overarching assumption of the house energy-saving. For this purpose, we used a deep section of the roofed terrace from the south, which is to protect the house from overheating during the summer heat. At the same time, big glazing allows for heating the rooms with solar energy in winter, when the sun is relatively low above the horizon and the sun's rays fall through the glazing directly inside the house. We also decided to close the shorter sides of the terraces with walls so that the east-west winds blowing in the open space do not cool the glassed south facade. In the closing walls, it was possible to locate small utility cells.

Thanks to the use of the technology of prefabricated roof trusses on the south side and in the north, it was possible to create deep arcades without the need for additional elements supporting. Thanks to the roofing from the north, we were able to give up the farm building, originally planned by investors as a free-standing shed in the garden. We reduced it to a room hidden under a roof, stretching along the front facade. Thanks to this we freed the garden from unnecessary cubature disturbing the view of the fields and the forest. Thanks to the use of a reversible heat pump and a heat recovery system, used air, flowing outside through the utility room, warms it and provides an additional buffer thermal from the north.

Materials. When selecting building materials, we tried to put accents in the right places. We focused on high-quality, healthy construction and building materials. We have reduced unnecessary elements and finishing materials to a minimum. In the construction of the house, mainly prefabricated technology was used. Bearing walls are made of prefabricated expanded clay aggregates. The roof truss was made of prefabricated, wooden trusses supported only on external load-bearing walls.12 cm thick recycled liquid polyurethane was used as a floor insulation layer where the main component is polystyrene waste. To improve heating efficiency anhydrite floor was used as the finishing material, which is characterized by high thermal conductivity. For the thermal insulation of the roof and attic, cellulose obtained from recycled paper was used. The same material was used as acoustic insulation in the partition walls.

▼项目更多图片

客服

消息

收藏

下载

最近