查看完整案例

收藏

下载

翻译

Following a proposal by MIT to create climate-change-fighting bubbles, here is a roundup of 10 inventions aimed at limiting the impact of architecture and design on our environment.

Creatives and scientists alike have come up with various innovations that seek to fight the ongoing climate crisis in which construction and manufacturing play a large part.

They range from large-scale planetary interventions – known as geoengineering – to smaller-scale ideas including using tree fragments instead of steel when constructing buildings and making bio-concrete tiles out of invasive species.

Below are 10 projects from Dezeen's archive that attempt to play a role in tackling climate change:

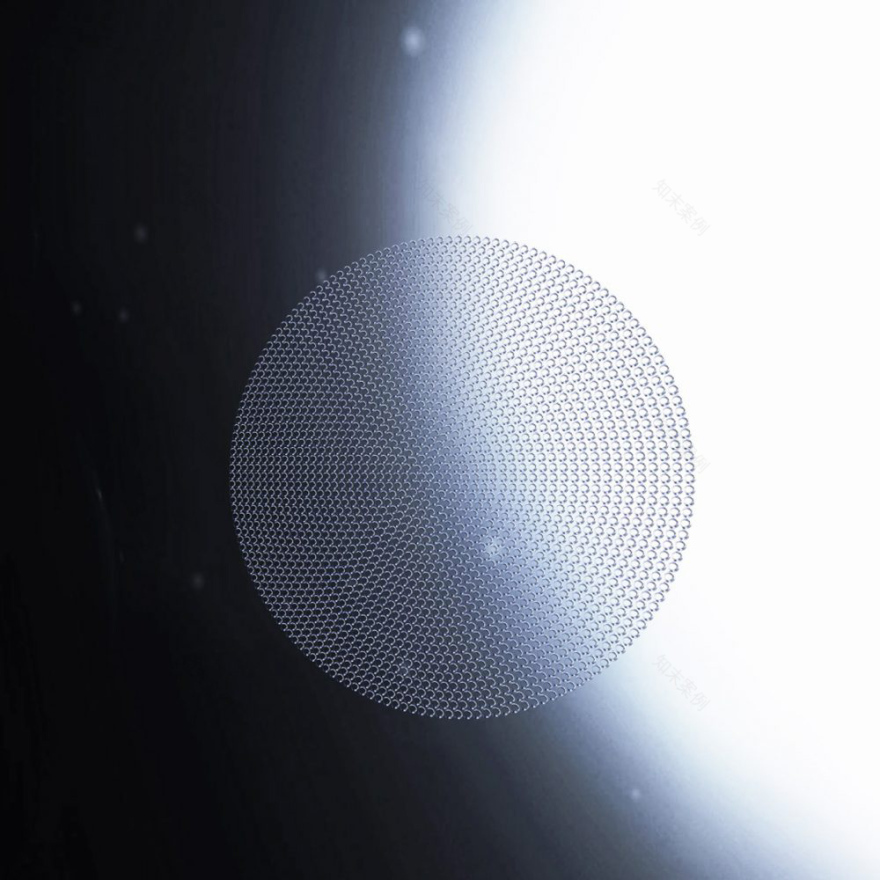

Image is courtesy of MIT

Space Bubbles by MIT

MIT researchers including architect Carlo Ratti have proposed the idea of floating a conglomeration of frozen bubbles at the point between the Earth and the sun where their gravitational pulls cancel out, which is called the L1 Lagrangian Point.

The Space Bubbles research project is a variation on the geoengineering concept of a solar shield. It would work by blocking out a portion of the incoming solar radiation, theoretically reducing the effects of global warming.

Find out more about Space Bubbles ›

Image is courtesy of the University of Cambridge

Photosynthesis-mimicking device by the University of Cambridge

This renewable energy device designed by scientists at the University of Cambridge mimics the natural process of photosynthesis – the way that plants create their own energy from the sun.

Formed from a slim sheet, the device produces oxygen and formic acid from water, carbon dioxide and sunlight. The sheet is made from photocatalysts, which are materials that absorb light to create a reaction. It does not require electricity or wires.

Find out more about this device ›

Photo is by Felix Amtsberg

Tree fork joints by MIT

Another project by MIT, the institute's Digital Structures research group has developed a construction technique where discarded tree forks replace traditional load-bearing joints in architecture projects. Tree forks are the pieces of wood where a trunk or branch splits into two.

The researchers have suggested that this system could reduce the environmental impact of construction by using natural and renewable wood rather than emissions-intensive materials such as steel to form the Y-shaped nodes that connect straight building elements.

Tree forks are also considered a reclaimed waste product when salvaged from the timber industry because only straight sections of trees are typically used to create furniture and other building materials.

Find out more about these tree fork joints ›

Bio-based carbon fibres at the German Institutes of Textile and Fiber Research

Carbon fibres are thin threads of almost-pure carbon crystals widely used in manufacturing thanks to their strong and lightweight properties. Scientists at the German Institutes of Textile and Fiber Research are working on producing the fibres from biomaterials rather than fossil fuels.

Head of carbon fibre development and new materials Dr Erik Frank is exploring ways of turning the plant-based material lignin, which is also a byproduct of the paper industry, into carbon fibres.

"The raw materials [for regular carbon fibre] come from petroleum but we're trying to move away from this," said Frank.

Find out more about these bio-based carbon fibres ›

Photo is by Anne Kinnunen

Sun-Powered Textiles by Aalto University researchers

Design and physics researchers at Aalto University in Finland concealed solar panels within the textile of this prototype jacket that was created to harvest energy from the sun without compromising on its appearance.

The team's intention was to design a machine-washable, energy-autonomous product that could power wearable devices including body sensors that measure humidity or temperature.

Find out more about Sun-Powered Textiles ›

Image is courtesy of MIT

Emissions-free cement by MIT

Researchers at MIT have developed an experimental production process that manufactures cement without releasing carbon dioxide into the atmosphere.

Using an electrochemical method that cleanly captures the carbon dioxide created from the process, the emissions are not released into the air even though they are produced.

At the end of last year, 40 leading cement and concrete manufacturers published a plan to eliminate carbon emissions from the environmentally harmful industry by 2050.

Find out more about this emissions-free cement ›

Image is courtesy of DS Automobiles

Carbon-capturing clothing collection by DS Automobiles

A bomber jacket, a trench coat and two T-shirts are included in a collection of clothing by French car brand DS Automobiles, where items are coated in living algae that sequesters carbon dioxide from the air and turns it into oxygen.

The garments must be exposed to sunlight and regular misting in order to function as they use the same photosynthesis process as plants.

"There are hopes that this technology can be incorporated within both the fashion and automotive world as we look towards the future and gain a better understanding of its real-world capabilities," said the founders of Post Carbon Lab, the London research studio that developed the algae layer.

Find out more about this clothing collection ›

Image is courtesy of Irene Roca Moracia and Brigitte Kock

Bio-concrete tiles by Brigitte Kock and Irene Roca Moracia

Designers Brigitte Kock and Irene Roca Moracia created bio-concrete tiles from Japanese knotweed and American signal crayfish shells.

The knotweed and fish are invasive species in the UK, causing significant ecological damage. By adding value to them, Kock and Moracia hope to incentivise their removal and help restore local biodiversity.

By replacing emissions-intensive concrete with a new material that also reduces the level of knotweed and crayfish in the environment, the tiles seek to combat climate change two-fold.

Find out more about these bio-concrete tiles ›

Image is courtesy of MIT

2DPA-1 by MIT

Chemical engineers from MIT have invented a new form of plastic that they say has twice the strength of steel and is also recyclable.

The project is dubbed 2DPA-1, which is the name for a type of polymer that self-assembles into sheets, making it malleable but highly durable.

Researchers at MIT hope the material could one day be used in buildings, reducing the need for other construction materials like steel and glass that use more energy to produce.

Find out more about 2DPA-1 ›

CobBauge by various researchers

A team of French and British researchers have updated the ancient building material cob to meet current thermal standards for architecture.

Traditionally, cob is a mixture of water, soil and fibres such as straw and hemp. The researchers bonded together two grades of cob to create a version that has an increased ability to trap heat while having a much smaller carbon footprint than current mainstream construction materials.

"While what we have come up with is without a doubt a modern interpretation of cob, we hope it will satisfy both the traditionalists and those looking for a hi-tech, energy-efficient material," said researcher Steve Goodhew.

Find out more about CobBauge ›

客服

消息

收藏

下载

最近