查看完整案例

收藏

下载

混合亚麻展亭是 Landesgartenschau 场地上的一座中心展览建筑,坐落在最近焕然一新的 Argen 河蜿蜒的河岸上。该展馆展示了斯图加特大学“建筑一体化计算设计与施工”(IntCDC)小组开发的一种新型木材与天然纤维混合的建筑系统,作为传统建筑方法的替代方案。这种独特的混合系统将薄型交叉层压木材(CLT)与机器人缠绕的亚麻纤维体结合在一起,创造出一种新颖的、资源节约型的建筑结构,这种建筑结构由当地的生物材料制成,与当地有着明显的联系。亚麻在历史上曾是当地纺织业的加工材料,其旧纺纱厂作为 Landesgartenschau 的一部分进行了翻新。展馆缓缓起伏的屋顶、环形的平面布局以及位于中央的气候花园,营造出一个与周围景观完美融合的展览空间。由可回收混凝土制成的地热激活的楼板为这座永久性建筑提供了全年舒适的使用环境。

The Hybrid Flax Pavilion constitutes a central exhibition building on the grounds of the Landesgartenschau, located on the winding banks of the recently revitalised Argen River. The pavilion showcases a novel wood-natural-fibre hybrid construction system developed by the Cluster of Excellence “Integrative Computational Design and Construction for Architecture” (IntCDC) at the University of Stuttgart, as an alternative to conventional building methods. The unique hybrid system combines thin cross-laminated timber with robotically wound flax fibre bodies to create a novel, resource-efficient building structure made from regional, bio-based materials with a distinct local connection. Flax was historically processed in the local textile industry, whose old spinning mill was renovated as part of the Landesgartenschau. The pavilion’s gently undulating roof, together with its circular floor plan and centrally located climate garden, creates an exhibition space that seamlessly integrates into the surrounding landscape. The geothermal activatable floor slab made of recycled concrete provides year-round comfortable use of the permanent building.

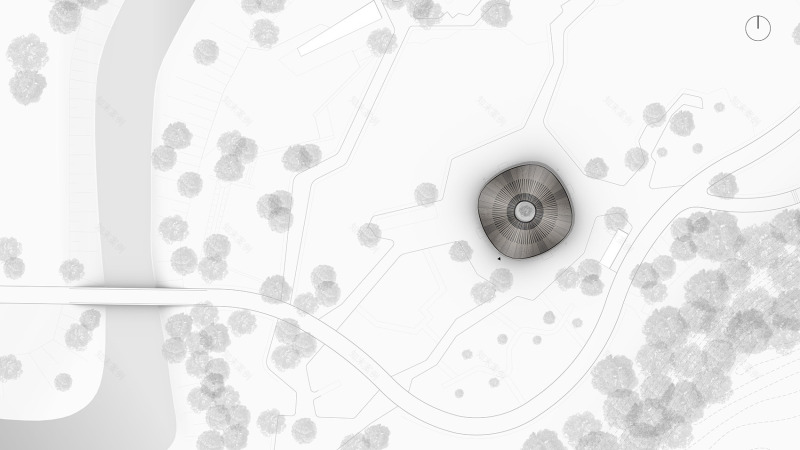

▼项目鸟瞰,Ariel view of the project©Roland Halbe

一座展示生物材料建设方法的永久展示建筑

A permanent exhibition building demonstrating novel bio-based construction methods

坐落于 Landesgartenschau 的郁郁葱葱的草地上,混合亚麻展亭提供了一块位于中央的展览空间。它的设计特征在于缓缓起伏的屋顶和环形的草皮立面,邀请游客们从各个方向进入令人惊艳的室内空间。全玻璃的外立面提供了全景视野,将室内与室外的景观完美融合。为了回应邻近的 Argen 河的节奏,缓缓起伏的屋顶创造了一种连续且独特的空间,提供了一种连接朝内和朝外的立面的深度。建筑的核心是一座气候花园,作为一个向内的庭院来提供自然通风和降温。和由回收混凝土和低碳水泥制成的地热激活楼板一起,这确保了在不使用太多设备的情况下,室内环境全年处于较为舒适的状态。

▼场地区位,site map©ICD/ITKE/IntCDC of University of Stuttgart

Situated on the lush grounds of the Landesgartenschau, the Hybrid Flax Pavilion provides a central exhibition space. Its design features an undulating roof and a circular glass facade that invites visitors to the striking indoor space from all directions. The fully transparent envelope provides panoramic views which seamlessly blend the interior of the building with the exterior landscape. Echoing the rhythm of the adjacent Argen River, the undulating roof creates continuous yet distinct spatial zones, providing a sense of depth that connects the inner and outer facades. At its core lies a climate garden, serving as an inner courtyard and facilitating natural cross-ventilation and cooling. Together with a geothermal activated floor slab made from recycled concrete and CO2-reduced cement, this ensures year-round indoor comfort with minimal building services.

▼向内的庭院,inner courtyard©Roland Halbe

展亭的屋顶由首个由交叉层压木材和亚麻纤维混合的结构组成,其中的亚麻纤维使通过无芯亚麻长丝缠绕生产的天然纤维体。20 混合纤维结构和常规的木板交替使用,组成了特殊的波浪般的起伏屋顶,笼罩在占地 380m²的展览空间之上。这一新颖的混合建筑系统的目的在于实现大跨度的无柱空间,同时尽可能少的使用材料,以此来发挥木材和天然纤维结构之间的协作。基于高精度的预加工和高完成度的算法设计过程,天花板上的 44 个组件在场地上仅耗费 8 天搭建完成。

▼结构轴测,structure axonometric©ICD/ITKE/IntCDC of University of Stuttgart

The pavilion’s roof constitutes the first-ever hybrid structure of cross-laminated timber plates and natural fibre bodies produced through core less flax filament winding. The 20 hybrid components alternate with regular timber plates to form the distinctive wave-like structure of the roof, which covers the 380m² exhibition space. The goal of this novel hybrid building system is to achieve expansive column-free space while minimizing material usage, thus leveraging the synergy between wood and natural fibre composites. The onsite assembly of all 44 ceiling elements was completed in 8 days owing to the integrative computational design process and high-precision pre-fabrication.

▼屋顶结构,roof structure©Roland Halbe

建筑的设计利用了综合性的计算机算法来融合从不同领域的专家们产出的成果,在研究和产业之间架起桥梁。这种方法不仅包括对纤维-木材混合结构的设计,也包括对传统建筑元素如立面和屋顶的接口的设计,考虑了它们连接的几何和结构需求。这一方法有助于灵活的迭代设计过程,使所有相关学科都能在发展的每一阶段灵活的调整和优化。因而,项目的设计,生产和施工仅耗费了 12 个月,展示了这一综合性联合设计手法的高效率。本着前沿研究和施工公司之间的双向的知识交流的精神,项目也展示了地区性的小制造公司和技艺高超的工匠们是如何建造高度创新的建筑的。

▼施工过程,construction progress©ICD/ITKE/IntCDC of University of Stuttgart

The building’s design makes use of integrative computational methods to seamlessly incorporate input from various specialists across different fields, bridging the gap between research and industry. This approach encompasses not only the design of hybrid fibre-timber components but also considers interfaces to conventional building elements like the facade and roof, taking into account their interconnected geometric and constructional requirements. This methodology facilitated a flexible, iterative design process, allowing for adjustments and optimizations at every stage of development across all involved disciplines. As a result, the design, manufacturing, and construction process took only 12months, demonstrating the effectiveness of this integrative Co-Design approach. In the spirit of two-way knowledge transfer between cutting-edge research and construction companies, the building also shows how highly innovative architecture can be built by regional, small enterprises and skilled crafts people.

▼屋顶结构,roof structure©ICD/ITKE/IntCDC of University of Stuttgart

运用自然纤维的新型混合建筑

Novel hybrid building system using natural fibers

纤维-木材混合系统利用了木材和自然纤维的独特品质,形成了一个高性能的轻型高效建筑结构。采用亚麻纤维成分加固薄木构件,有利于施工行业对快速生长资源的运用,从而更有效地利用当地的木材储备来满足对木材的大量需求。该建造系统开发的目的是按照可再生建筑的原则,通过对构件进行分离,实现未来的材料再利用或回收。混合材料的目的是实现高度可变的简单支撑的梁式结构。纤维体形成的底面主要承受拉力荷载,而木板则承受压力,并构成屋顶围护结构的表面。它们共同提供了必要的强度和刚度,以承载阿尔卑斯山脚下的高雪负荷。

▼屋顶构成,roof composition©ICD/ITKE/IntCDC of University of Stuttgart

▼构件组成, elements composition©ICD/ITKE/IntCDC of University of Stuttgart

The fibre-timber hybrid system leverages the distinctive qualities of timber and natural fibres, resulting in lightweight, effective building components with superior performance. Incorporating flax fibre components to reinforce the thin wooden elements facilitates the use of fast-growing resources for the construction industry, allowing the significant demand for wood to be met more effectively from locally available timber reserves. The construction system is being developed to enable future material reuse or recycling through the sorted separation of components, following principles of circular construction. The hybrid components aim to achieve a simply supported, beam-like structure with a variable structural height. The fibre body forms a bottom surface that primarily bears tension loads, while the timber panel manages compression forces and constitutes the surface for the roof enclosure. Together they provide the strength and stiffness necessary to carry the high snow loads at the foot-hills of the Alps.

▼屋顶结构,roof structure©ICD/ITKE/IntCDC of University of Stuttgart

通过研究和技术的发展,不断从建筑要求、结构分析、制造限制和材料特质中获得反馈信息,对纤维体的设计不断完善。它由多个依次缠绕的亚麻纤维层组成。主脊梁层与横梁方向一致,在跨度中心起着底部绳索的作用。扇形的面层逐渐将力传导向边缘的支撑,而视觉上占主导地位的网格层则形成均匀的纤维网,以达到所需的结构完整性。两处额外的角落强化层加强了纤维之间的互相作用,在结构较为薄弱的区域提供额外的支撑。

▼受力分析,tension & compression analysis©ICD/ITKE/IntCDC of University of Stuttgart

Throughout the research and development process, the design of the fibre body was continuously informed by feedback from architectural requirements, structural analysis, fabrication constraints, and material properties. It consists of multiple, sequentially wound flax fibre layers. The primary spine layer aligns with the beam direction, acting as a bottom cord at the centre of the span. The fan layer gradually disperses loads to the edge supports, while the visually dominant lattice layers create a uniform fibre mesh to achieve the required structural integrity. Two additional corner reinforcement layers enhance fibre interaction and provide additional reinforcement in structurally critical areas.

▼屋顶结构,roof structure©ICD/ITKE/IntCDC of University of Stuttgart

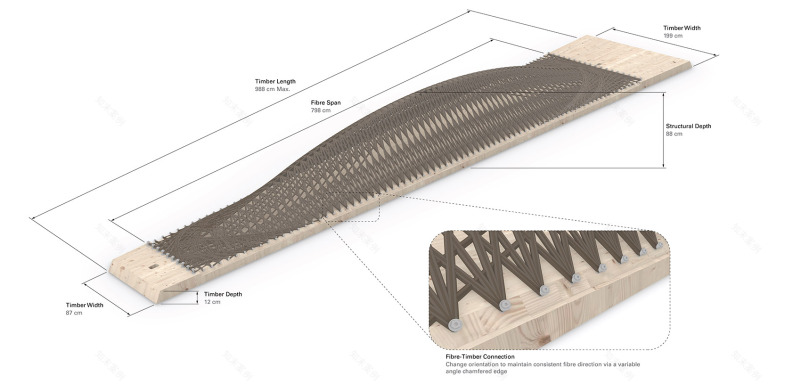

简单支撑的纤维-木材混合材料覆盖了直线距离约 8.6 米的跨度。精心放置的 120mm 厚的正交层积木板(CLT)构成了建筑的主要框架和缓缓起伏的屋顶。木板使用五轴机床制造,包括一系列用于木材-纤维-面板连接的通孔,以及不断改变角度以配合纤维连接不同方向的倒角边缘。亚麻纤维体通过螺钉固定在每两块 CLT 板的下方,组成混合材料。通过全尺寸的荷载测试,校准了有限元模型和对材料系统的结构完整性的确认。

▼亚麻纤维固定过程,manufacture process©ICD/ITKE/IntCDC of University of Stuttgart

The simply supported, fibre-timber hybrid components cover an 8.6-meter span between linear supports. The radially arranged 120mm thick cross-laminated timber (CLT) plates constitute the primary framework and create the undulating roof profile. The timber plates were manufactured using a 5-axis milling machine and include a series of thru-holes for the timber-fibre-facade connections as well as chamfered edges that continuously change their angle to match the varying orientations of the fibre connections. Flax fibre bodies are affixed by screws beneath every second CLT plate, establishing the hybrid components. Full-scale load tests allowed for the calibration of finite element models and confirmation of the material systems’ structural integrity.

▼屋顶结构,roof structure©ICD/ITKE/IntCDC of University of Stuttgart

从机器原型设计到工业纤维缠绕成型

From robotic prototyping to industrial filament winding

在纤维元素的发展和生产过程使用的去芯纤维缠绕成型技术,可以根据特定的结构、建筑和材料要求,有选择地沉淀材料。对比传统的纤维材料制造过程,这种材料不需要对表面进行打磨,因为成型的框架是和纤维元素一起设计的,所以最终成型的纤维元素体在缠绕成型的过程中是所有纤维段相互作用的平衡状态。该项目要求对无芯纤维成型过程的进一步调整,来适应自然亚麻纤维材料系统和混合材料中纤维体的独特几何构成。

▼制造过程,fabrication process©ICD/ITKE/IntCDC of University of Stuttgart

The coreless filament winding process utilised in the development and production of the fibre elements allows for the selective local deposition of material driven by specific structural, architectural, and material requirements. In contrast to conventional fibre composite fabrication processes, this is achieved without the need for a surface mould, as the winding frame is co-designed with the fibre element so that the element’s final fibre body emerges in the winding process as the equilibrium state of all fibre segments interacting. This project required further adaptation of the coreless filament winding process to accommodate the natural flax fibre material system and unique geometric form of the fibre body of the hybrid component.

▼夜景,night view©ICD/ITKE/IntCDC of University of Stuttgart

因为采用了正曲率的表面,该纤维几何体呈现出与以往不同的几何形态。一般来说,正曲率表面智能通过模具来制作,但该组件同时采用了正高斯和负高斯曲率区域。为了实现这一目标,缠绕成型框架包含一个“脊柱”,可使部件在其纵向上具有正曲率,在横截面上具有负曲率、结构深度和曲率半径,同时提供必要的结构,使框架能够自我支撑。围绕框架一圈的锚点是根据几何表面的法线特别定位的,以维持纤维方向的一致性并且将力从木材传导到纤维束上,这对于混合结构的有效性来说极为重要。

▼“脊柱”结构,“spine” structure©ICD/ITKE/IntCDC of University of Stuttgart

This fibre geometry represents a departure from previous geometries because of its use of positive surface curvatures. Typically, positive curvatures are only achievable by a mould, yet this component employs areas of both positive and negative Gaussian curvature. To achieve this, the winding frame includes a “spine” that allows for the positive curvature of the component in its longitudinal direction as well as negative curvature, structural depth, and radius of curvature in its cross-section, all while providing the necessary structure to make the frame self-supporting. Anchor points around the perimeter of the frame were specifically oriented based on the normal of the geometric surface to maintain consistent fibre direction and properly transmit forces from the timber into the fibre bundles, a requirement paramount to the effectiveness of the hybrid component.

▼夜景,night view©ICD/ITKE/IntCDC of University of Stuttgart

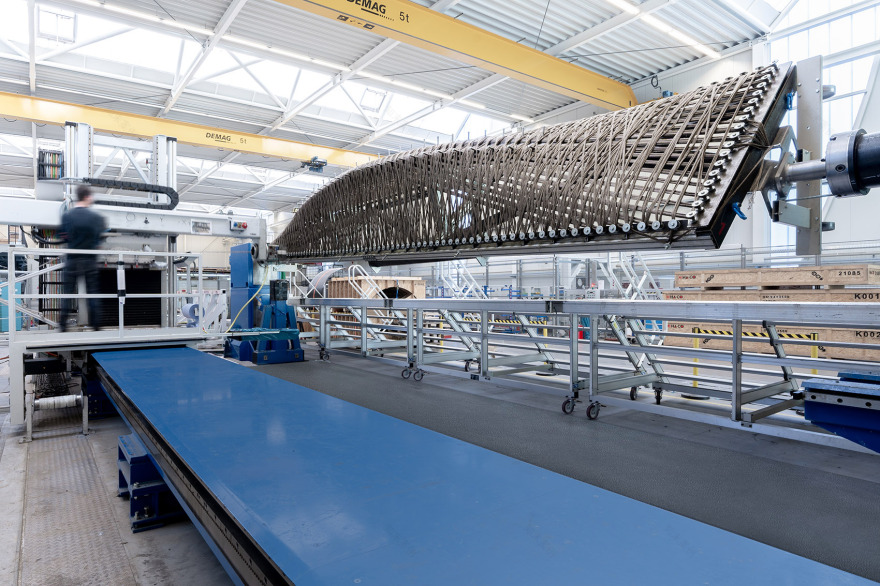

斯图加特大学使用这一定制的框架,通过配备定制末端执行器的六轴机械臂缠绕一系列原型,对几何形状、纤维模式和制造工艺进行了测试和改进。在原型完成和结构评估后,最终成果被交付给工业合作伙伴,使用五轴工业纤维缠绕机进行批量生产。制造规划直接集成到计算设计流程中,定制工具将纤维组件的几何数据转换为可执行的机器代码,从而简化了从设计到制造的工作流程,并成功缩小了研究与工业之间的差距。

▼生产过程,fabrication process©ICD/ITKE/IntCDC of University of Stuttgart

Using this custom frame, the geometry, fibre patterns, and fabrication processes were tested and refined at University of Stuttgart through a series of prototypes wound by a 6-axis robotic arm equipped with a custom end effector. After the prototypes were completed and structurally evaluated, the finalized design was handed over to the industrial partner for serial production using a 5-axis industrial filament winding machine. The fabrication planning was directly integrated into the computational design process and a custom tool converted the geometric data of the fibre component into executable machine code, streamlining the design-to-fabrication workflow and successfully bridging the gap between research and industry.

▼夜景,night view©ICD/ITKE/IntCDC of University of Stuttgart

斯图加特大学作为“建筑一体化计算设计与施工”卓越研究群体的一部分,正在继续开展基于计算的生物混合建筑系统的研究。

Research into computationally enabled, bio-based hybrid building systems is being continued at the University of Stuttgart as part of the Cluster of Excellence “Integrative Computational Design and Construction for Architecture”.

▼夜景,night view©Roland Halbe

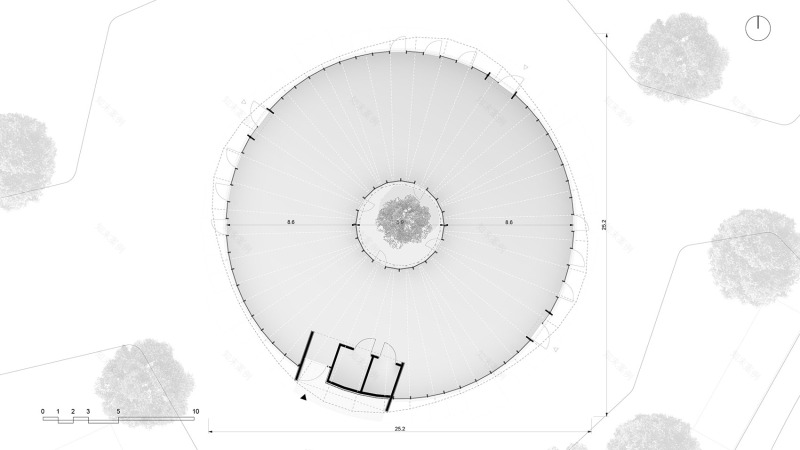

▼屋顶平面,roof plan©ICD/ITKE/IntCDC of University of Stuttgart

▼一层平面, ground floor plan

©ICD/ITKE/IntCDC of University of Stuttgart

▼结构平面, structure plan©ICD/ITKE/IntCDC of University of Stuttgart

▼立面, elevation©ICD/ITKE/IntCDC of University of Stuttgart

▼剖面, section©ICD/ITKE/IntCDC of University of Stuttgart

PROJECT PARTNERS

Cluster of Excellence IntCDC – Integrative Computational Design and Construction for Architecture, University of Stuttgart

ICD Institute for Computational Design and Construction

Prof. Achim Menges, Rebeca Duque Estrada, Monika Göbel, Harrison Hildebrandt, Fabian Kannenberg, Christoph Schlopschnat, Christoph Zechmeister

ITKE Institute for Building Structures and Structural Design

Prof. Dr. Jan Knippers, Tzu-Ying Chen, Gregor Neubauer, Marta Gil Pérez, Valentin Wagner

with support of:

Daniel Bozo, Minghui Chen, Peter Ehvert, Alan Eskildsen, Alice Fleury, Sebastian Hügle, Niki Kentroti, Timo König, Laura Marsillo, Pascal Mindermann, Ivana Trifunovic, Weiqi Xie

Landesgartenschau Wangen im Allgäu 2024

Karl-Eugen Ebertshäuser, Hubert Meßmer

Stadt Wangen im Allgäu

HA-CO Carbon GmbH

Siegbert Pachner, Dr. Oliver Fischer, Danny Hummel

STERK abbundzentrum GmbH

Klaus Sterk, Franz Zodel, Simon Sterk

FoWaTec GmbH

Sebastian Forster

Biedenkapp Stahlbau GmbH

Stefan Weidle, Markus Reischmann, Frank Jahr

Harald Klein Erdbewegungen GmbH

Harald Klein

PROJECT COLLABORATIONS

Scientific Collaboration:

IntCDC Large Scale Construction Laboratory

Sebastian Esser, Sven Hänzka, Hendrik Köhler, Sergej Klassen

Further Consulting Engineers:

Belzner Holmes und Partner Light-Design

Dipl.-Ing. (FH) Thomas Hollubarsch, Victoria Coval

BiB Concept

Dipl.-Ing. Mathias Langhoff

Collins+Knieps Vermessungsingenieure

Frank Collins, Edgar Knieps

Moräne GmbH – Geotechnik Bohrtechnik

Luis Ulrich M.Sc.

Spektrum Bauphysik & Bauökologie

Dipl.-Ing. (FH) Markus Götzelmann

wbm Beratende Ingenieure

Dipl.-Ing. Dietmar Weber, Dipl.-Ing. (FH) Daniel Boneberg

lohrer.hochrein Landschaftsarchitekten DBLA

Building Approval:

Landesstelle für Bautechnik

Dr. Stefan Brendler, Dipl.-Ing. Steffen Schneider

Proof Engineer

Prof. Dr.-Ing. Hans Joachim Blaß, Dr.-Ing. Marcus Flaig

Versuchsanstalt für Stahl, Holz und Steine, Karlsruhe Institute of Technology (KIT)

Prof. Dr.-Ing. Thomas Ummenhofer, Dipl.-Ing. Jörg Schmied

MPA Materials Testing Institute, University of Stuttgart

Melissa Lücking M.Sc., Dipl.-Ing (FH) Frank Waibel

Construction Collaboration

ARGE- Leistungsbereich Wärmeversorgungs- und Mittelspannanlagen

Franz Miller OHG

Stauber + Steib GmbH

客服

消息

收藏

下载

最近