查看完整案例

收藏

下载

翻译

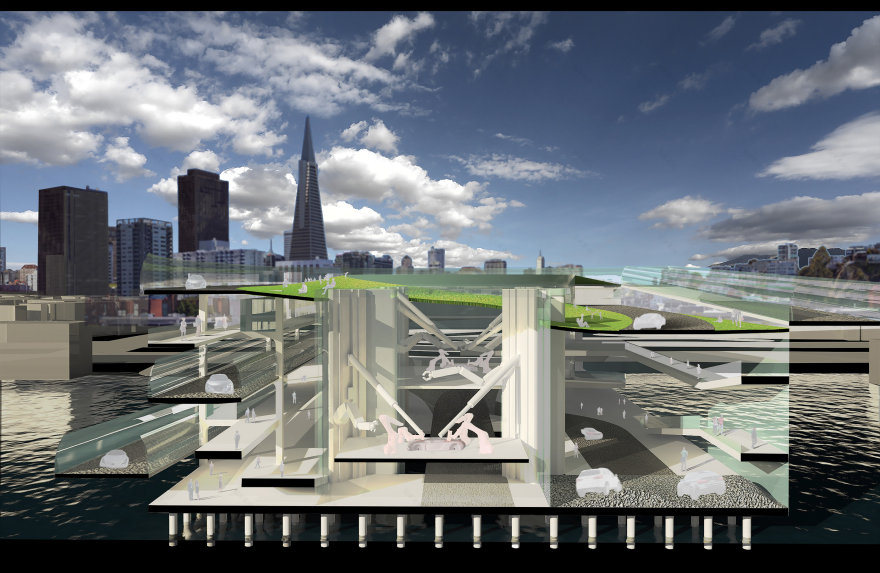

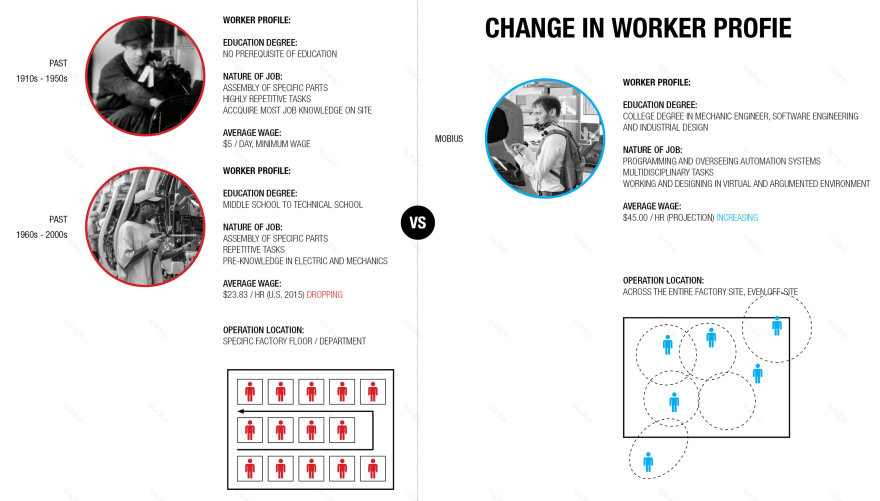

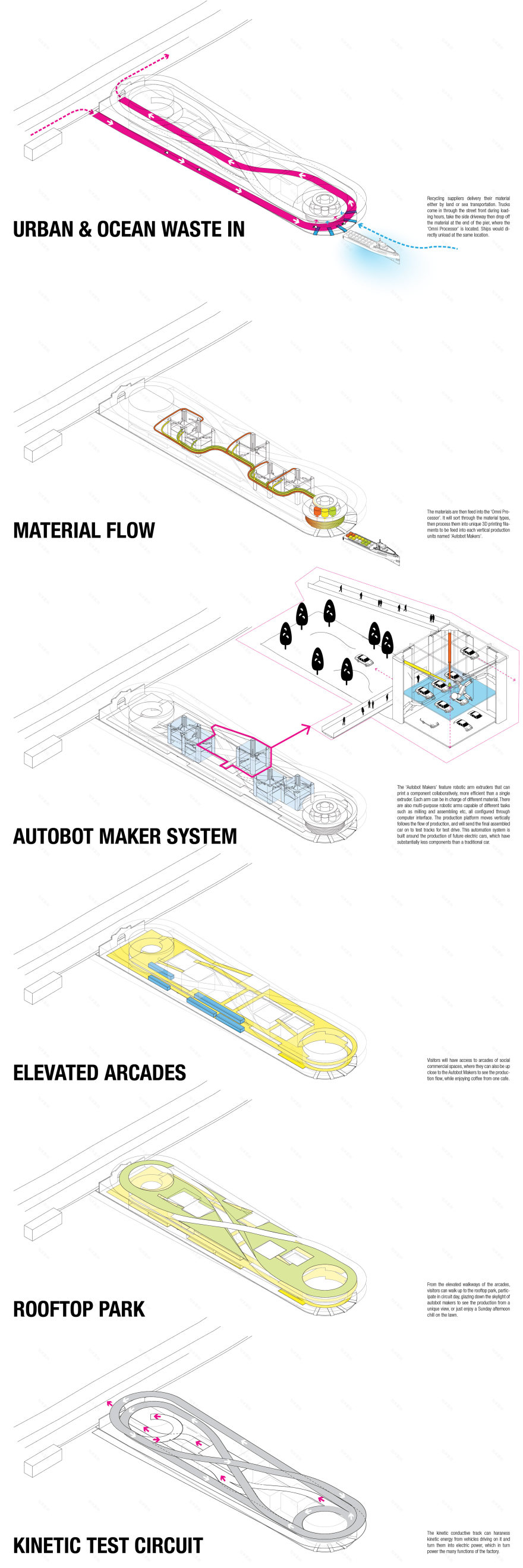

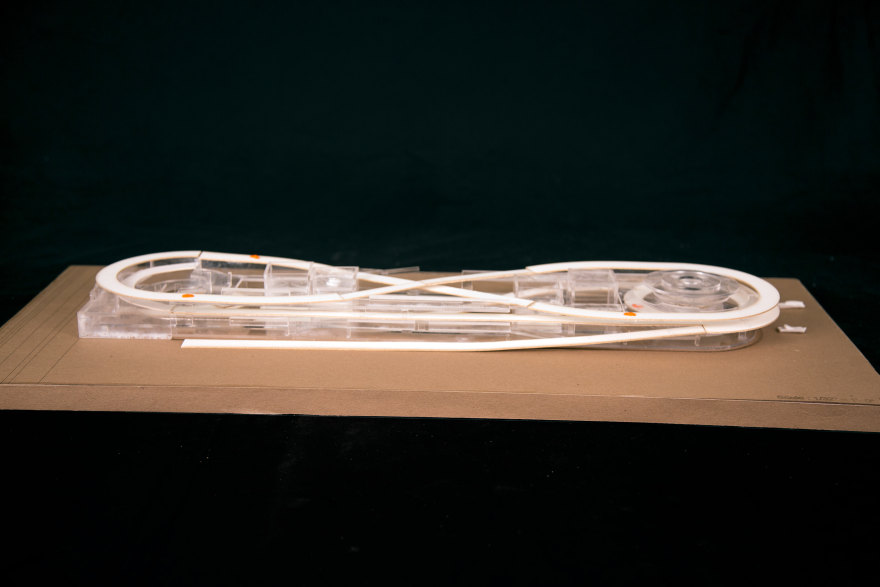

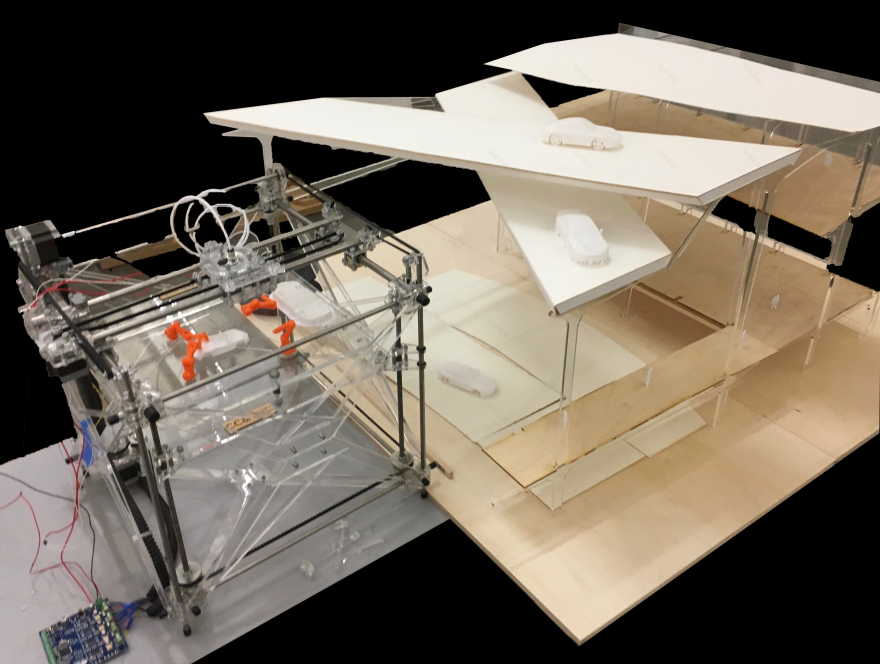

Mobius ParkAdvance Studio - Future FactoryMobius considers a future where manufacturing automation becomes total, releasing the factory floor from its historical horizontality. By using robots Mobius explores the re-arrangement of car factories around vertical axes.The traditional Detroit car factory features more than two million square feet of floor space, mostly dedicated to assembly lines in which workers stand around cars, each worker repetitively performing a single task. As automation has taken root, many of these human workers have been replaced by single function robots which are bolted to the ground where a human used to stand.Mobius challenges this now-strange paradigm: spaces designed originally to optimize human efficiency are now being used inefficiently by robots. Robots, having no need to be bolted to the ground in rows, and gaining no efficiency from performing the same motion over and over, can work more efficiently in much smaller footprints by being re-oriented along a vertical axis and given multiple functions. The assembly line is no longer one-directional.The Mobius assembly line vastly reduces the horizontal footprint of car manufacturing processes whilst simultaneously reducing the safety concerns inherent in traditional assembly lines. By "vertically integrating" the assembly line, heavy manufacturing shrinks to the point that it can take root in an urban context at Pier 9.

客服

消息

收藏

下载

最近