查看完整案例

收藏

下载

3月28日,在一场中国汽车工业史上最成功的产品发布会之后,小米汽车终于面世,24小时预定超过8.8万辆,成为现象级的产品。随之曝光的,是雷军在发布会上重点推荐的小米汽车超级工厂。小米汽车超级工厂位于北京亦庄经济开发区,由weico建筑事务所完成整体规划、厂前区的超级工厂店及办公楼建筑设计、研发中心建筑设计、工厂整体形象设计和景观概念设计等,项目目前已经基本全面竣工。通常来说,很少有独立建筑事务所能承接汽车工厂的整体设计,而weico之所以能在竞争中脱颖而出,归功于团队本身对汽车产业和工业美学的深入理解。

On March 28, following one of the most successful product launches in the history of the Chinese automotive industry, Xiaomi SU7 finally debuted. In just 24 hours, over 88,000 vehicles were pre-ordered, making it a phenomenal product. Alongside this, Lei Jun’s keynote presentation also highlighted the Xiaomi EV Factory. Xiaomi EV Factory is located in the Beijing Yizhuang Economic Development Zone. Weico Architects was responsible for the overall planning, the design of the super factory store and office building in the front zone, the design of the research and development center, the overall factory image design, and the landscape concept design. The project is now nearly complete. Typically, few independent architectural firms can undertake the comprehensive design of an automotive factory. Weico Architects stood out in the competition due to the team’s deep understanding of the automotive industry and industrial aesthetics.

▼超级工厂综合楼,Super Factory Complex ©陈曦工作室

从内燃机时代到电车时代,一辆汽车的生产组织已经经历了翻天覆地的变化。但除去所有子系统的供应链,最终整车的组装仍然遵循着基本一致的逻辑:压铸-车身-涂装-总装。小米汽车超级工厂在此之上,还增加了办公、研发、体验和新车交付,从而把创造、生产和消费同时整合在一个大园区内,是汽车建筑领域里少见的案例。小米汽车超级工厂距离北京市中心约23公里,占地7万余平方米,总建筑面积超过40万平方米。

From the internal combustion engine era to the electric vehicle era, the organization of automobile production has undergone revolutionary changes. However, excluding the supply chain for all subsystems, the final assembly of a vehicle still follows a fundamentally consistent logic: casting, bodywork, painting, and final assembly. Xiaomi EV Factory goes beyond this by incorporating offices, research and development, experience centers, and new car delivery services, thereby integrating creation, production, and consumption within one large campus. This is a rare example in the field of automotive architecture. Xiaomi’s super factory for automobiles is approximately 23 kilometers away from the center of Beijing, covering an area of over 70,000 square meters and having a total construction area of more than 400,000 square meters.

▼项目区位,Project location© weico

工厂部分包含以上所说的四个核心环节:冲压车间和压铸车间,负责把金属原材料加工成车身所需的各种形状,备受关注的小米泰坦合金和9100吨超级大压铸即出现在这里;随后,金属部件在焊接车间被机器人精确地连接在一起,构成完整的车身框架,也就是人们通常所说的车壳。焊接完毕的车身进入涂装环节,机器人喷漆通常会进行八次,而最终面漆的颜色往往是一个重要卖点,比如此次小米SU7的系列色。最后一个环节是总装,也是人工比例最高的一个环节,所有的部件会依次被安装在车身上,包括轮胎、座椅、电机、软件调试等,直至一辆完整的小米汽车呈现在缘定的“主人”眼前。

Xiaomi EV Factory is located about 23 kilometers from downtown Beijing, covering over 70,000 square meters with a total building area exceeding 400,000 square meters. The factory includes the four core processes mentioned: the stamping and die-casting workshops, which shape raw metal materials into various car body parts. The highly anticipated Xiaomi Titan Alloy and the Hyper Die-Casting T9100 cluster are also housed here. Next, the metal parts are precisely welded together by robots in the welding workshop to form the complete body frame, or car shell. The welded body then moves to the painting process, where robots apply eight coats of paint, with the final color being a significant selling point, such as the series colors of the Xiaomi SU7. The final stage is assembly, the most labor-intensive part, where all components, including tires, seats, motors, and software adjustments, are sequentially installed onto the car body, until a complete Xiaomi car is presented to its destined “owner”.

▼超级工厂综合楼,Super Factory Complex ©陈曦工作室

这四个环节的流程非常严谨,工艺布局对空间设计的配合度要求很高。在与工艺设计多轮沟通后,为最大程度保障核心生产区的高效运作,我们将生产外所有复杂的功能压缩至东侧500多米长的狭窄条状区域。在这里有跨越新车测试道的空中连廊、完全对外开放的体验店、汽车研发和评审中心、办公空间、体验赛道等等功能。仅针对顾客的新车体验道就占地2万平米左右,在寸土寸金的北京可谓奢侈。整个超级工厂的功能繁多、建筑复杂,每个部分的设计都需要设计师从输入条件出发,进行深入的可行性研究,推导出最终设计方案。为便于感受,我们在此仅以最容易理解的交付中心为例,来说明本项目的设计过程。

▼东侧的建筑涵盖研发、办公、体验、交付等众多功能,The building on the east side encompasses numerous functions such as research and development, office work, experience, and delivery ©weico

The processes of these four stages are highly rigorous, demanding a high degree of spatial coordination for the process layout. After multiple rounds of communication with the process design team, to ensure the highest efficiency of the core production area, we condensed all complex functions outside of production into a narrow strip area over 500 meters long on the east side. This area includes an elevated corridor crossing the new car test track, a fully open experience store, an automotive research and evaluation center, office spaces, and an experience track. The new car experience track alone occupies about 20,000 square meters, which is quite luxurious in the land-scarce city of Beijing.The entire super factory features a multitude of functions and complex architectural designs. Each section’s design requires designers to start from input conditions, conduct in-depth feasibility studies, and derive the optimal design solutions. To illustrate the project’s design process in a more understandable way, let’s take the delivery center as an example.

▼超级工厂鸟瞰 ,Aerial view of the Super Factory © weico

凡是买过车的人都体验过提车的过程。实际上,这个提车的流程是由汽车生产商根据自身产品特点、消费者心理、预估销售量和空间可能性综合制定出来的。一般来说,新车出厂后会停放在停放区,在顾客来提车之前被清洗、整备、更新系统,等待主人的光临。车主按照约定时间到达门店之前,新车会被移至门店内的交付区。在这个流程里,设计师需要注意车辆吞吐量,从而计算出各个环节的空间需求大小。

Anyone who has bought a car has experienced the process of picking it up. In fact, this delivery process is formulated by the automobile manufacturer based on their product characteristics, consumer psychology, anticipated sales volume, and spatial constraints. Typically, after a new car leaves the factory, it is parked in a designated area where it undergoes cleaning, preparation, and system updates before awaiting its owner’s arrival. Prior to the customer’s scheduled visit to the dealership, the new car is moved to the delivery area inside the showroom. In this process, designers need to consider vehicle throughput to calculate the spatial requirements for each stage.

▼交付中心只是众多功能中的一环,也是最为普通消费者所熟悉的场景

Delivery centers are just one of the many functions, and the most familiar scenario for average consumers ©weico

从车主到达门店开始,一切就会按照操演熟练的流程进行了:销售人员会引导车主检查自己的新车、办理保险和牌照等事宜,随后进行新车交付仪式,再到体验道上看看爱车的性能,最后离开厂区。整个过程通常来讲需要用时1小时45分钟,这个时间配合门店希望达到的销售量,再根据核心营业时间长短和每个步骤的氛围要求,可以推演出最终的基本空间大小、布局、流线。所有对建筑空间布局的一次次优化、室内动与静的把握,都是建立在这个基础之上。

Once the car owner arrives at the dealership, everything proceeds smoothly according to a well-practiced procedure: sales staff guide them through inspecting their new vehicle, handling insurance and registration, and then conducting the new car delivery ceremony. Following this, owners can experience their vehicle’s performance on the test track before departing the factory premises. Typically, this entire process takes about 1 hour and 45 minutes. This timeframe, tailored to meet dealership sales targets and core operating hours, as well as the ambiance required for each step, determines the final spatial needs in terms of size, layout, and flow. Every optimization of the architectural layout and the balance between dynamic and static elements is grounded in these considerations.

▼设计之前的推演:以交付中心为例,Deduction before design: the delivery center as an example ©weico

这些小小的“复杂性”只是众多待解决问题中的一点,所有这些“问题”的解决方案最终都被包裹进了一个极简的方盒子里,这就是设计中有趣的地方。我们顺着从消费者到研发者,从公开到私密的逻辑来梳理一遍这些“问题”:

These minor “complexities” are just one facet among many issues to be resolved. The solutions to all these “problems” ultimately fit neatly into an elegantly simple framework, which is the intriguing aspect of design. Let’s trace through these “problems” from consumer to developer, from public to private logic.

▼整体功能逻辑和落位示意,Overall functional logic and placement schematic ©weico

1.交付中心功能应该与超级工厂门店相连,也与场地北侧的新车体验公园及测试道相连,以方便展示和体验,这是建筑面向公众的一面。

2.从展示体验区域,重要的来访者应该能直接进入受控的“红区”,即二楼的企业内部接待区,由此经过89米长的玻璃连廊进入工厂内部参观。

3.这条连廊串联工厂内的参观环线,同时也负责连接场地东南侧涉密级别较高的研发实验楼、企业办公和餐厅,这里是非常私密的内部空间。

4.研发实验楼的使用者可以从地面进入封闭的厂区,直接接触厂区内南北向1027米长的专业测试道。

5.测试道上设置了多种路面以测试车辆性能,最高允许时速可达120公里/小时,是新车出厂前的最后一关。横跨测试道上方的,就是刚才提及的玻璃连廊。到这里,所有功能完成闭环。

▼不同功能在一个空间内的共生,Symbiosis of different functions in one space ©weico

1. The delivery center should be connected to the super factory store and to the new car experience park and test track on the north side of the site, facilitating display and experience. This is the public-facing aspect of the building.

2. From the display and experience area, important visitors should be able to directly access the controlled “red zone,” which is the second-floor corporate reception area. From there, they can enter the factory’s interior through an 89-meter-long glass corridor.

3. This glass corridor connects the factory’s internal tour route and links to the highly confidential R&D laboratory building, corporate offices, and restaurant on the southeast side of the site, forming a very private internal space.

4. Users of the R&D laboratory building can access the enclosed factory area from the ground level, providing direct access to the 1,027-meter-long north-south professional test track within the factory.

5. The test track features various road surfaces to evaluate vehicle performance, with a maximum permissible speed of 120 kilometers per hour, serving as the final checkpoint before a new car leaves the factory. The glass corridor mentioned earlier spans above the test track. Here, all functions form a complete loop.

▼小米汽车超级工厂一角,A corner of Xiaomi Auto Super Factory ©陈曦工作室

我们在方案初期从建筑师的想象出发,结合当时的功能探讨,曾经有过数版更加“有表现力”的设计稿,但最终对设计影响最大的,还是小米自身的设计哲学。小米的设计哲学是一切都要简化再简化,直到只有最必要,但必须最好。从产品精神和成本控制上来说这是合理的选择,也对建筑设计提出了更严苛的工业设计级要求。

At the initial stage of the project, starting from the architect’s imagination and incorporating the functional discussions at that time, we had several more “expressive” design drafts. However, the most significant influence on the final design was Xiaomi’s own design philosophy. Xiaomi’s design philosophy is to simplify everything down to only the most essential elements, but those elements must be the best. From the perspectives of product ethos and cost control, this is a rational choice, and it also places more stringent industrial design-level demands on the architectural design.

▼超级工厂综合楼,Super Factory Complex ©陈曦工作室

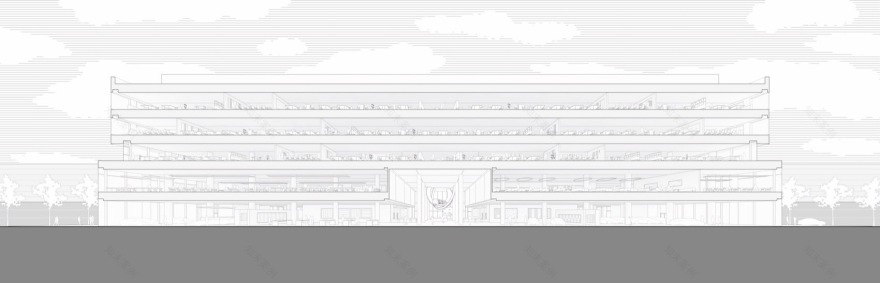

前文所述复杂功能的最终体现是三个极简的方盒子,其中两个叠加成为综合楼高点和入口形象。综合楼南北长120米,宽43米,建筑共五层,楼体不高但体量感庞大,其中第三层做了退进处理,使建筑上下分为两部分,上部呈现一定的漂浮感。上下分区也对应建筑功能分区,首二层基本以公共功能为主,四五层则主要是内部办公功能。

The complex functions described earlier are ultimately embodied in three minimalist rectangular boxes, with two of them stacked to form the prominent feature and entrance of the building. The complex extends 120 meters north to south and 43 meters wide, with five floors in total. Although not tall, the building has a substantial presence. The third floor is recessed, dividing the building into two sections and giving the upper part a floating appearance. This division also reflects the functional layout: the first and second floors are primarily for public use, while the fourth and fifth floors are mainly designated for internal offices.

▼超级工厂综合楼,Super Factory Complex ©陈曦工作室

综合楼的大堂两层通高,东西穿透,大堂中心是最近大火的莫比乌斯环和悬空的蓝色SU7,大堂里引入了星巴克为访客提供餐饮服务。大堂两侧分别是小米汽车科技体验中心和新车交付中心。整个大堂及两个侧厅设计简洁融洽,落落大方,这是一个完全对公众开放的空间,前来体验、试驾的人络绎不绝,以年轻人居多。缤纷多彩的小米SU7、充满好奇的来访人群,给予了这个工业建筑一份跳跃的活力。

The lobby of the complex spans two floors with an open east-west corridor. At its center are the popular Möbius ring and the suspended blue SU7. The lobby includes a Starbucks, providing refreshments for visitors. On either side of the lobby are the Xiaomi Automotive Technology Experience Center and the New Car Delivery Center. The design of the lobby and the two side halls is simple and harmonious, creating an elegant and welcoming space. This fully public area attracts a constant stream of visitors, mainly young people, who come to experience and test drive the cars. The vibrant Xiaomi SU7 and the inquisitive crowd bring a lively energy to the industrial building.

▼大堂空间-莫比乌斯环和悬空,SU7 Lobby space – Möbius ring and overhang SU7 ©陈曦工作室

▼大堂空间-莫比乌斯环和悬空,SU7 Lobby space – Möbius ring and overhang SU7 ©陈曦工作室

▼展厅与交付中心,Showroom & delivery center ©陈曦工作室

▼展厅与交付中心,Showroom & delivery center ©陈曦工作室

建筑外立面使用金属和玻璃幕墙,上层采用1.5米为模数,下层以1.6米为模数。由于该尺寸的水平长度已经有一定的压迫感,立面上没有再增加任何刻意强调水平延伸感的装饰件,而是尽量把各垂直模块的拼接做到极致,以凸显简洁的科技感。由于功能不同,上下两部分的立面选用了不同的玻璃,下半部是全封闭玻璃幕,较为通透以服务于展示和体验;上半部选用了反射度较高的玻璃,增加了模块间距,并在间距里隐藏了室内开启扇,这样整体增加了一些金属感和工业制造感,也在一定程度上改善了室内日照并保护室内空间的私密。最终,干净的玻璃与金属材料拼接出的立面实现了较完美衔接,精细度和质感都达到了汽车工程人所追求和能理解的表现。

▼综合楼幕墙细节,Complex curtain wall detail ©weico

The building’s exterior facade features metal and glass curtain walls, with the upper floors using a module of 1.5 meters and the lower floors a module of 1.6 meters. Given the somewhat imposing horizontal dimensions, no additional elements were added to emphasize horizontal extension. Instead, the vertical modules were meticulously joined to highlight a sleek, technological aesthetic. Due to differing functions, the upper and lower sections of the facade use different types of glass. The lower section features a fully enclosed, highly transparent glass curtain wall to facilitate display and experience, while the upper section uses glass with higher reflectivity, increased module spacing, and concealed operable windows in the gaps. This design enhances the metallic and industrial feel, improves indoor lighting, and protects privacy. Ultimately, the seamless integration of clean glass and metal materials achieves a perfect connection, with a level of precision and texture that meets the standards and understanding of automotive engineers.

▼综合楼幕墙细节,Complex curtain wall detail ©陈曦工作室

▼综合楼幕墙细节,Complex curtain wall detail ©陈曦工作室

主入口采用不锈钢外雨棚与内门斗一体化设计,使室内外空间有一定的衔接延续。一体化的设计与结构配合,也减轻了外挑雨棚的厚重感,15米长、3米高的雨棚最终三边收边都做到了80毫米。▼雨棚 – 门斗剖面示意,Canopy – Door hopper section ©weico

The main entrance features an integrated design of an exterior stainless steel canopy and an interior vestibule, creating a seamless transition between indoor and outdoor spaces. This integrated design and structure reduce the perceived bulkiness of the protruding canopy. The 15-meter-long, 3-meter-high canopy is finished with 80-millimeter edges on all three sides, achieving a sleek and refined appearance.

▼综合楼门厅,Complex lobby ©陈曦工作室

连接综合楼和车身车间的连廊整体跨度89米,内外完全通透,使用者可以从这里俯瞰专业测试道。连廊内部基本呈纯白色,为保持它的纯净感,连廊上的浅灰结构柱用车漆工艺完成最终处理,表面非常细腻。▼厂房模块,Factory modules ©weico

The corridor connecting the complex building and the body workshop spans 89 meters and is completely transparent inside and out, allowing users to overlook the professional test track. The interior of the corridor is predominantly pure white to maintain a clean aesthetic. The light gray structural columns in the corridor are finished with automotive paint techniques, giving them a smooth and refined surface.

▼空中连廊 ,sky corridor ©陈曦工作室

▼空中连廊 ,sky corridor ©陈曦工作室

▼空中连廊内景,Interior view of the sky corridor ©孙晨

▼生产区整体印象 ,Overall impression of the production area ©陈曦工作室

当你步入小米汽车超级工厂店,在明亮的体验中心内向北望去,就能看见在文章开头提到的2万平米体验赛道。这一大片绿地像是北京外环的一片中央公园,疾驰而过的新能源汽车、跃跃欲试的人群、舒缓优美的绿草地,在道路两侧樱花树的映衬下,极大地增强了人们对其背后产品以及产品所代表理念的信心。

When you step into the Xiaomi EV Factory and look north from the bright experience center, you can see the 20,000 square meter test track mentioned at the beginning of the article. This expansive green area resembles a central park on Beijing’s outer ring, with new energy vehicles speeding by, eager crowds, and serene, beautiful lawns. Cherry blossom trees line the road, greatly enhancing people’s confidence in the products and the ideas they represent.

▼北侧新车试驾体验区,North side of the new vehicle test drive experience area ©陈曦工作室

▼北侧新车试驾体验区,North side of the new vehicle test drive experience area ©陈曦工作室

小米汽车超级工厂是一个集合中国最高端新能源汽车研发、生产、体验、销售于一体的超级项目,也是工业建筑领域里一次成功的新尝试。

Xiaomi EV Factory is a mega project integrating the research, development, production, experience, and sales of China’s most advanced new energy vehicles, marking a successful new venture in the field of industrial architecture.

▼总平面图,Master plan ©weico

▼综合楼首层平面布局,Ground floor plan of the complex ©weico

▼综合楼二层平面布局,First floor plan of the complex ©weico

▼综合楼标准层平面布局,Standard floor plan of the complex ©weico

项目名称:小米汽车超级工厂

项目类型:汽车研发、生产、办公、展示、交付、销售、体验

设计方:weico建筑事务所 PR@weico.work

项目设计:2021.12-2022.07

完成年份:2023年

设计团队:孙伟、段芸、孙晨、梁梓、秦伟

项目地址:北京亦庄经济开发区

用地面积:718,046㎡

建筑面积:408,164㎡

摄影版权:陈曦工作室

合作方:中国汽车工业工程有限公司

客户:小米汽车

材料:金属、玻璃、金属夹芯板、金属波纹板

Project name: Xiaomi Auto Super Factory

Project type: automobile R&D, production, office, display, delivery, sales, experience

Design: weico architects

PR@weico.work

Design year: 2021.12-2022.07

Completion Year: 2023

Leader designer & Team: Wei Sun, Yun Duan, Chen Sun, Zi Liang, Wei Qin

Project location: Yizhuang Economic Development Zone, Beijing

Site area: 718,046㎡

Gross built area: 408,164㎡

Photo credit: Chen Xi Studio

Partner: China Automotive Industry Engineering Co.

Clients: Xiaomi Automobile Co.

Materials: metal, glass, sandwich panels, corrugated panels

客服

消息

收藏

下载

最近