查看完整案例

收藏

下载

FEATURE WALL – A DESIGNER’S PERSPECTIVE

Most facades are about the final finish, the layer that looks fresh and new. But behind this shiny facade there is often a complicated sandwich. Each layer designed, installed and co-ordinated with other design and site teams. The feature wall at 50 Finsbury Square was in part such a project. The scope to form a wave of stone that rises from the ground and cascades at its apex. Resulting in a randomised pattern above the foyer entrance. The feature wall is visible from both sides at the upper levels which added some degree of complication to the fixing strategy.

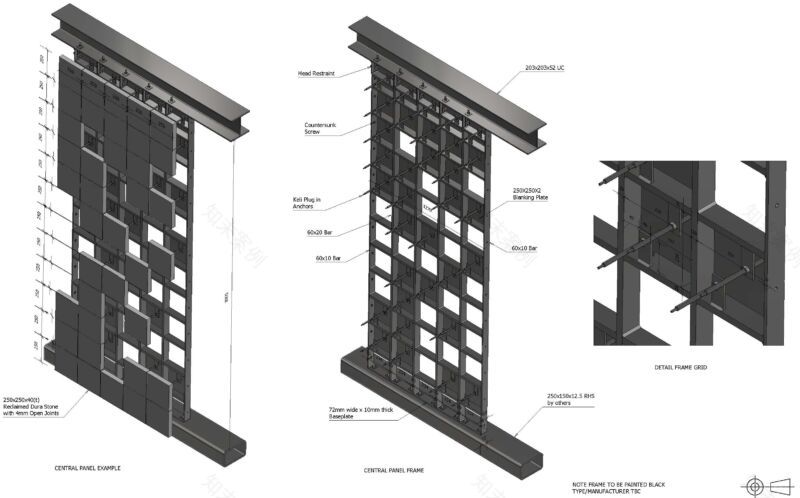

The substrate for the stonework, comprises of 2 types of block-work intersected with steel box section windposts. Spanning the entrance to the foyer is a large lattice beam, with a void above to be filled with a pattern of stone blocks interspersed with voids.

The stone used was Jura stone reclaimed from the original façade, consisting of 250x250x40(t) with 4mm open joints with each stone effectively standing alone. The design office had to come up with a solution of how to support each stone individually, while allowing for the versatility and accuracy of being able to position each at the prescribed depth. Additionally we had to design a feature frame capable of supporting the stone above the beam.

The Problem

The challenge was to provide an architectural frame that is robust enough to resist the cantilevering stone pieces at various distances, and able to be standardised to allow for the random nature of the stone pattern. Finally we needed to be able to secure the stone without any visible signs to the exposed sides and face of the stone.

Japanese Frame

The Japanese frame is a lattice frame that is made from black powder coated steel and provides the points of attachment for the stone pieces.

In this area the grid pattern is a mixture of stone cubes and voids, with several stones being exposed on all sides. The objective was to support the stones with no visible fixings to the face.

We used Keil anchors bolted to the Japanese frame, having calculated with a minimum of 2 M12 threaded rods we could suspend a stone to carry its self-weight and the lateral load to the required distance of 250mm. (3)

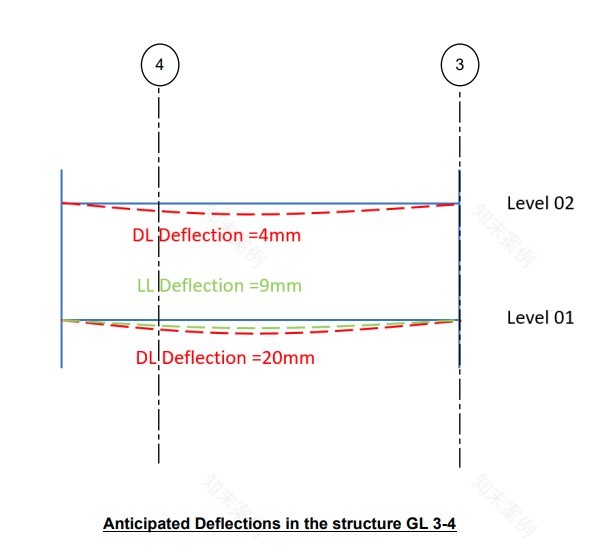

Facades and particularly internals are a squeeze where every millimetre counts. Under the frame is a large box section forming part of the lattice beam., which is there to support our Japanese frame, OAG glazing and the windpost supports. The windpost supports are used at the termination of the blockwork either side of the opening. A major factor was the deflection of this beam. The stone pattern had to stay line and level, not compressing the thin 4mm open joints, there was no room for any sagging of the stone at the beam.

Several options were considered, including a curved beam which wasn’t a popular idea, to curve a lattice beam would be problematic to manufacture and install. Or shimming the frame. We plumped for manufacturing the frame in several full height sections, which were bolted side by side on site. Panelising the frame, allowed for easier manufacturing and transport. But also allowed for storing the stone on the beam and installing in sections, allowing for adjustments as the beam was loaded.

The Japanese frame was powder coated and a feature of the wall. It was important that the frame aligned with the prescribed set out of the stone. This meant fashioning a frame that fitted snuggly between the Windposts either end, avoiding any clashes with the glazing frame behind. Resulting in a 60mm wide frame panel connected top and bottom similarly to a Windpost. The fixing of the frame had to allow tolerances plus deflection allowances at the head and be able to resist the reaction loads generated at the base, but without the benefit of a large baseplate.

Although the black powder coated frame is a feature of the wall, the actual fixings of the stone cubes needed to be hidden when viewed from the glazing side. We decided to use thin unobtrusive blanking plates to hide the fixings. These needed to be welded on, but the heat of the welding process had to be considered as it could distort the frame and damage the powder coating. The expertise of GA Fixing’s welders and a sample trial enable us to form a sequence that kept the blanking plates ultra thin and with almost unnoticed welds. Unlike most stone projects, the structure and its fixing method was as much part of the feature as the stone itself.

Windposts

Due to the structure being blockwork, it was interspersed with fire protected windposts We coordinated at an early stage to align the posts with the central line of the stone. Due to the fire protection, we couldn’t fix into the posts. We had to span over each post and secure the stone with a Unistrut strap, which acted as the base fixing for the Keil anchors. We also had to allow for the inclusion of the trims, making certain there would not be a clash.

Cladding the Beam

Spanning over the foyer entrance is a mighty lattice beam, designed by S.A.H. Luton Ltd which is over 10metres in length. Its primary function to carry the loads of the OAG glazing panels and our own Japanese frame and stonework. Originally we looked at bringing this in in sections as it would have been easier to transport but the splice plates would have clashed with where the stone was going to to go, so in the end we brought the lattice beam in in one piece.

While the top of the lattice beam was supporting everyone’s frames, the lower portion of the beam is there to act as the substrate to our 1

st

row of stones above the foyer entrance. This still meant we had to come up with a system to span the gaps of the lattice and secure our stone. Wherever possible we try and use standard products and in this instance Unistrut channels were fixed to the beam to allow the stone to be fixed back to.

Trims

With internal projects there is always a high level of detail at the boundary of the works. No one wants an ugly end to a clean lined feature.

A cavity closer was required around the edges of the wall with the projecting stone panels. This needed to fit exactly the profile of the stone pattern as it came forward or dropped back. While also allowing for any deviations in the concrete upstand where it moved off its parallel line to our stone line, the tolerances of the supporting steelwork and blockwork.

The trims are black powder coated shadow gaps, which are highlighted with recessed lighting. Working with Aluminium Profile Supplies Ltd we surveyed the structure, manufacturing the trims to suit exactly the site variations between the structure and the stonework. The profiles were designed to be linked together with a seamless joint. And most importantly to leave a consistent line between trim and edge of stone. (9)

Keli Anchors

Traditionally stones are fixed using 4 dowels, but for this wall, the joints were open to view by the public and we needed a hidden fixing. The Keil Anchor is installed into the back of the stone with an undercut anchor that expands into the stone and can be fixed to a variety of other bolts. We then used a resin anchor to fix into the blockwork behind. We arrived at 11 variations for the various depths of stone and support conditions. At lower level to resist impact we used 3 fixings per stone and higher up we used 2 per stone. Where the blockwork was deemed unsuitable to resist the loads of the self-weight of the stone, we used a more traditional method of a frame cramp.

Conclusion

Be it brick, render or stone, one of its main roles is to look aesthetically pleasing and hide all the ponderous workmanlike structure behind. But for this feature wall, part of its beauty is to show the fixing strategy, displaying the framework and how it forms part of the sandwich of the wall, while also hiding all the anomaly and irregularities.

Tom Richards, Design Manager Szerelmey

客服

消息

收藏

下载

最近