查看完整案例

收藏

下载

架构师提供的文本描述。缝制木材壳的研究使用机器人和传感机制,结合服装设计和工业缝纫技术,探索一种新的方法,以制造定制木材结构和重新与传统工艺。

Text description provided by the architects. The Sewn Timber Shell investigates the use of robotics and sensing mechanisms in combination with garment design and industrial sewing techniques to explore a new way of fabricating tailored wood structures and re-engaging with traditional craftsmanship.

相关研究对时尚界仍然采用的传统服装图案和连接技术进行了研究,并在新的材料语境下对它们进行了重新阐释。用薄胶合板代替织物,建立了材料柔韧性与刚度之间的变化关系,从而为新型材料体系引入了承载能力。缝纫在服装设计中起着类似的作用,因为缝纫可以从覆盖身体的平片材料中裁剪出三维弯曲的形状。如果应用在建筑尺度上,接缝就变成了连接,形成了以木材弹性弯曲为基础的材料,从而产生了结构能力和空间围护结构。

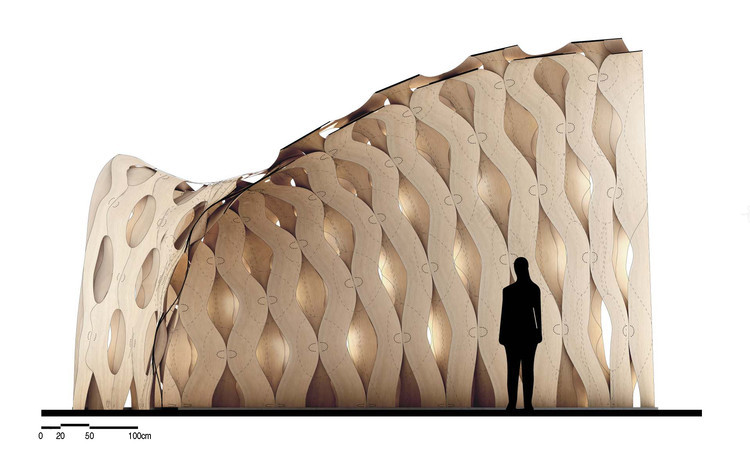

The related research studies traditional garment patterning and connection techniques still used in fashion today and re-interprets them in a new material context. Fabric is replaced by thin sheets of plywood, which establishes an altered relation between material pliability and stiffness and thus introduces loadbearing capacity to the novel material system. Sewing plays a similar role as in garment design, as the seams enable tailoring three-dimensional curved shapes from a flat sheet material that envelope the body. If applied on an architectural scale, the seams become connections that shape the material based on the elastic bending of wood, which creates structural capacity and spatial enclosure.

一种自适应的机器人制造过程能够实现必要的缩放和处理图案形状与材料行为之间复杂的相互关系。与重复制造过程(自动化依赖于预定和完全定义的步骤的执行)不同,这里使用传感技术来实现实时合成材料计算和机器人制造的工作流。在此过程中,裁剪工件的形状被重复扫描。这些片段包含以前以标记的形式建立的连接,这些标记被实时跟踪,以生成机器人运动。在整个过程中,木片是连续添加和永久连接的缝制连接。一个定制的数字建模设计工具被用来导出一个多孔的、起伏的、三层结构的系统,该系统将材料特性、制造约束和装配顺序有机地集成在一起。这一复杂的发挥之间的物质性和物化导致了一个缝壳,扩展了木材建筑的特点,同时展开了一个独特的纹理和空间的清晰度。

An adaptive robotic fabrication process enables the necessary scaling-up and the handling of the complex interrelations between the patterning shapes and the material behavior. In contrast to repetitive manufacturing processes, where automation relies on the execution of predetermined and fully defined steps, here sensing technology is employed to enable a workflow that synthesizes material computation and robotic fabrication in real time. In this process, the shape of the tailored work piece is repetitively scanned. The segments contain previously made connections in the form of markers that are tracked live for the generation of the robotic movement. Throughout that process, the wood pieces are sequentially added and permanently joined by a sewn connection. A custom digital modelling design tool is used to derive a porous, undulating, triple-layered system that coherently integrates material properties, fabrication constraints and assembly sequence. This intricate play between materiality and materialization results in a sewn shell that extends the characteristics of wood architecture and at the same time unfolds a unique textural and spatial articulation.

2017年缝制木材壳是由斯图加特大学计算设计和建筑研究所(ICD)和上海同济大学数字设计研究中心(DDRC)合作开展的项目,是中德研究项目“基于可持续建筑机器人制造的性能设计方法”(GZ 1162)的一部分,该项目由中德研究中心资助。

The Sewn Timber Shell 2017 is a collaborative project by the Institute for Computational Design and Construction (ICD) at Stuttgart University and the Digital Design Research Center (DDRC) at Tongji University, Shanghai that forms part of the Sino-German Research Project “Performative Design Methodologies based on Robotic Fabrication for Sustainable Architecture (GZ 1162)” funded by the Sino-German Research Centre.

该项目将在深圳中国领先的设计博物馆-设计学会的首届展览上展出。

The project will be on show at the inaugural exhibition "Minding the Digital" of the Design Society, China's new leading design museum in Shenzhen.

Architects DDRC Tongji University, ICD University of Stuttgart

Location Haiyuan 2nd Rd, Futian Qu, Shenzhen Shi, Guangdong Sheng, China

Project Team ICD University of Stuttgart – Martín Alvarez, Prof. Achim Menges DDRC Tongji University – Prof. Philip Yuan

Area 17.5 m2

Project Year 2017

Photographs Bai Yu

Category Small Scale

Manufacturers Loading...

客服

消息

收藏

下载

最近