查看完整案例

收藏

下载

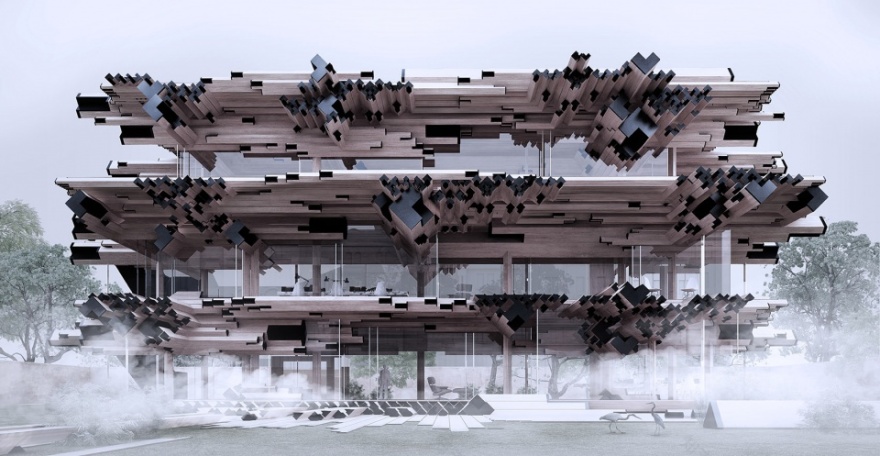

Gilles Retsin Architecture将木材结构与增强现实、自动化技术相结合设计了Royal Academy (皇家学院)中Real Virtuality装置。Gilles Retsin Architecture对技术的应用并没有停留在视觉层面,而是利用微软全息透镜(Microsoft’s Hololens)实时组装模块,探索如何将增强现实技术应用于实际制造之中。全息透镜在展示空间中投射出一个预先设想的数字化模型,显现出这些像乐高一样的模块的位置和连接节点。由于体块是模块化的并且不是固定不变的,因此可以实时对设计进行调整。

Gilles Retsin Architecture combines timber construction with Augmented Reality and Automation at the Royal Academy. Exploring how Augmented Reality could be used for fabrication, rather than merely visualisation, Gilles Retsin Architecture used Microsoft’s Hololens to assemble modular timber building blocks in real-time. The Hololens overlays a digital model of the envisioned design in the exhibition space, indicating the position of the lego-like blocks and their connections. As the blocks are modular and the design is not fixed, adaptations to the design could be done in real-time.

▼装置概览,overview of the installation

Gilles Retsin解释说:“我们利用AR技术直接从数字模型中向现场的工作团队发送指令。AR能够帮助我们理解一个完全自动化的建造过程是什么样子的,在这个过程中,数字模型直接与现场的人和机器进行交流。模块化是这项工作的驱动力,它并非是那种每一部分都是唯一的并且只有一个适宜位置的拼图,因此装置的部件可以放置在任何位置,让模型与建造具有适应性和交互性。”

Gilles Retsin explains “ We used AR to send instructions directly from the digital model to the team working on site. AR therefore helps us understand what a fully-automated construction process would look like, where a digital model communicates directly with people and robots on site” “ Modularity is a driver for this process to work, rather than constructing a jigsaw puzzle, where every part is unique and has only one possible position, in this case parts can be placed anywhere and enable adaptation and interactivity between the model and the construction”

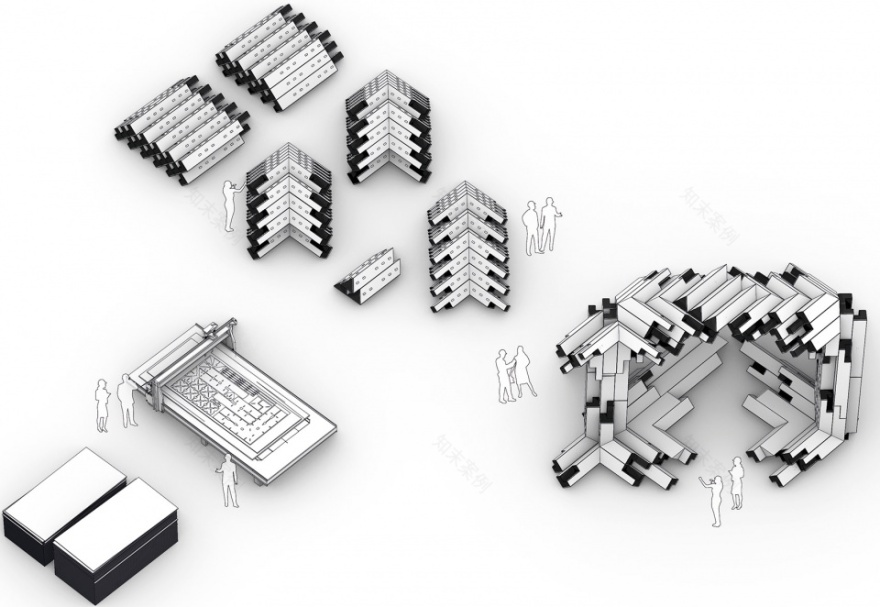

▼工作流程,workflow

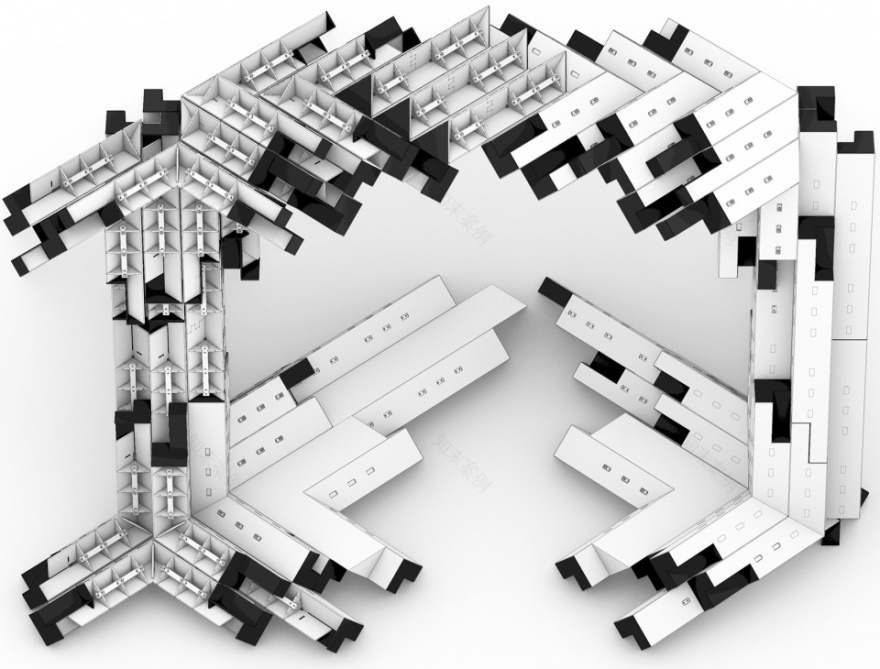

▼装置设计图解,installation diagram

从建筑上讲,这个装置只是未完全实现的大型建筑的一个片段。作为一个片段,装置呈现出一种未完成的状态,但是能够让参观者理解和体验在这个未实现的大型建筑中居住是怎样的一种感觉。一系列的长椅可以让参观者坐下来休息,观看ScanLAB Projects 和 Keiichi Matsuda拍摄的视频,装置既是一个背景也是展览的主体。

Architecturally, the installation is a mere fragment of a larger design, which is not completely materialised. As a fragment, the installation is permanently unfinished, but lets visitors understand and experience what the larger building would be like to inhabit. A series of benches allows visitors to sit down and rest, while watching videos by ScanLAB Projects and Keiichi Matsuda. The installation is therefore both a neutral backdrop and a subject of the exhibition.

▼装置呈现一种未完成的状态,但是能够让参观者理解和体验在这个未实现的大型建筑中居住是怎样的一种感觉,the installation is permanently unfinished, but lets visitors understand and experience what the larger building would be like to inhabit

▼一系列的长椅可以让参观者坐下来休息,a series of benches allows visitors to sit down and rest

Gilles Retsin 说:“人们越来越清楚的意识到木材将成为21世纪最重要的建造材料之一。人们关注的重点往往是木材的可持续性,却低估了木材施工可自动化的程度和由此降低施工成本的能力。与AR和机器人技术等数字化技术相结合,木材施工能够给我们一种全新的建筑,既令人兴奋、具有可持续性又能够适用于更多人的需求。”

Gilles Retsin “ It’s becoming more and more clear that timber will be one of the most important materials for construction in the 21th century. The emphasis is often on the sustainable aspects of timber, but what is underestimated is also the degree to which timber construction can be automated and therefore reduce the cost of construction. Combine with digital technologies such as AR and robotics, timber construction can give us a completely new kind of architecture that is both exciting, sustainable and accessible to the many.”

▼装置天花板横梁景象,view of the beam

▼构造细节,construction detail

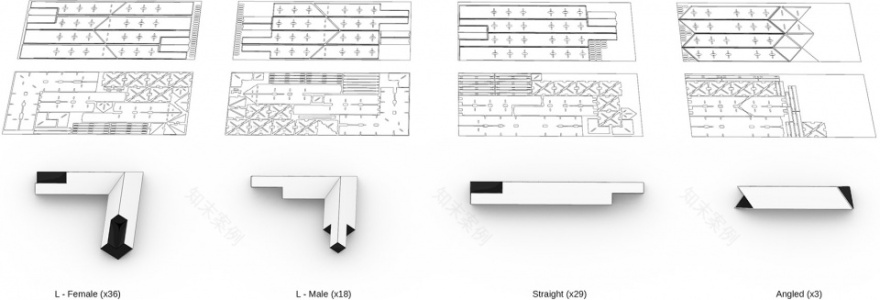

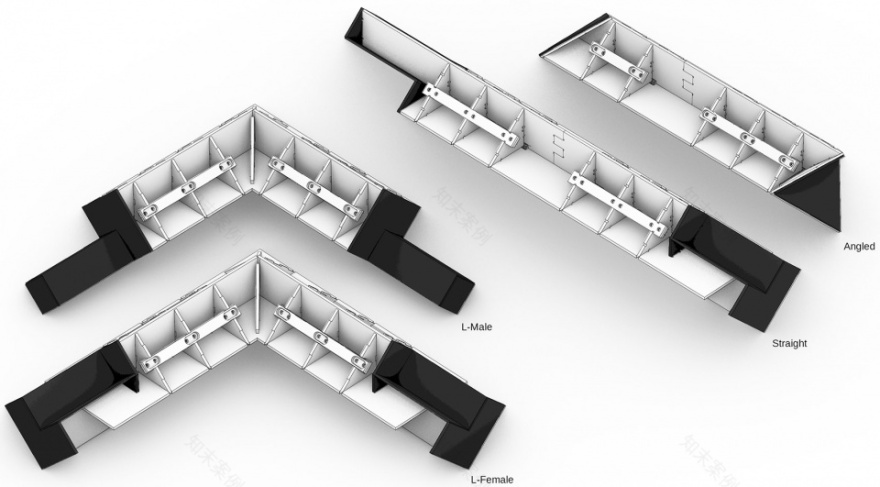

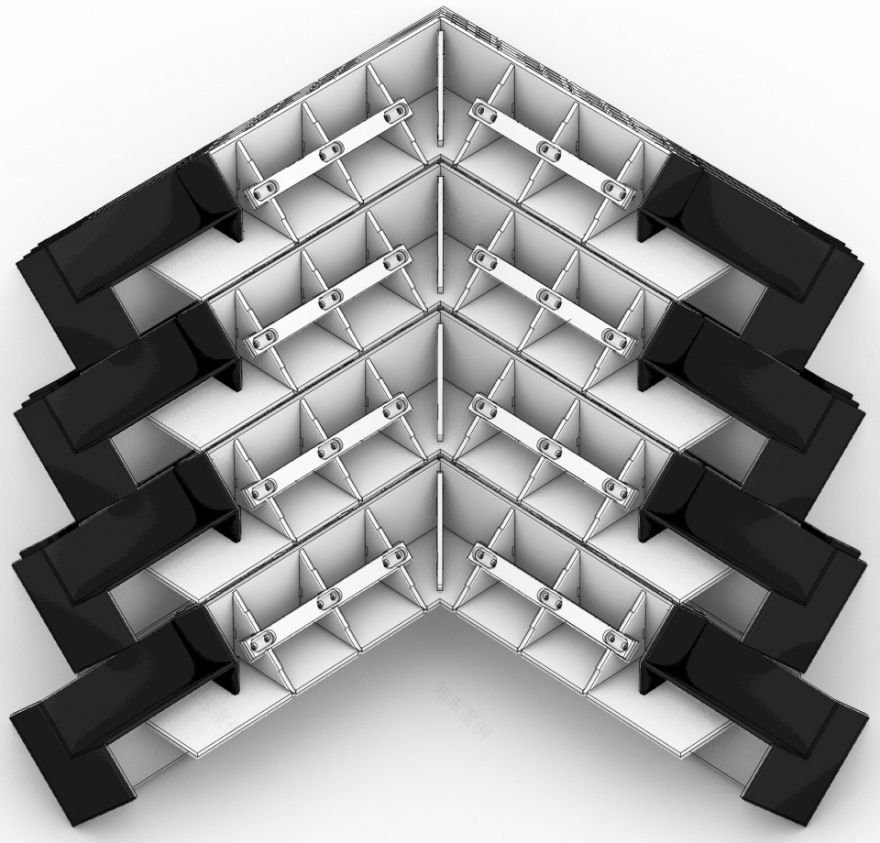

每一块胶合板构造模块都由一套的9mm和12mm软胶合木模板经过数控铣削后拼装而成。元件经过设计组装后能够安装在装置的任何结构部位,它们本身结构相对较弱但大量元件经过组合后能够形成一个足够坚固的体系。建造体块通过拉力连接在一起,这些拉力由元件间特定重复的连接点处放置的横向钢杆件所产生。

Each plywood building block consists of a 9mm and 12mm soft plywood sheets that has been CNC-milled in a kit of parts. The elements are then engineered to be able to perform in any structural situation within the installation. In themselves, every element is relatively weak, but the redundant combination of the elements establishes a strong structure. The building blocks are kept together under tension with lateral steel rods placed in specific, repeating connection points between the elements.

▼基本元件切割模板,elements sheets

▼元件类型,element types

▼元件组合,element assemblies

▼大量组合起来的元件能够建造一个足够坚固的体系,the redundant combination of the elements establishes a strong structure

▼建造体块通过拉力连接在一起,这些拉力由特定重复的连接点处放置的横向钢杆件所产生,the building blocks are kept together under tension with lateral steel rods placed in specific, repeating connection points between the elements

装置探索了虚拟物体所能够产生的真实效果。从90年代起,建筑师们认为虚拟现实(VR)是完全孤立于“现实”的东西,是一项探寻无限空间的技术,不受重力、预算或者客户的约束。但是今天,增强现实(AR)与日常生活的交织日益加深。计算机视觉算法应用到手机、交通管理、闭路电视摄像等等设备中,在自动化生产中的应用也越来越多。在Royal Academy的这一装置让人们第一次看到了木材建筑与自动化和算法相结合所能呈现的效果。Gilles Retsin之前曾在其他项目,例如2017年塔林建筑双年展(

点击这里查看完整项目

)和2015年布鲁塞尔附近Wemmel的多户住宅中探索过这一施工方式。

The installation explores the real effects produced by something virtual.Since the 90’s, architects have thought of Virtual Reality (VR) as something completely separate from the “real reality”, a space for unlimited spatial exploration, not bound by gravity, budgets or clients. However, today, Augmented Reality (AR) is more and more interlaced with the everyday. Computer vision algorithms are embedded in the cellphone, traffic control, CCTV camera’s etc. AR is also increasingly used to automate labour.The installation at the Royal Academy gives a first glimpse of what timber architecture could look like when combined with automation and algorithms. Gilles Retsin has previously explored these construction method for projects such as the Tallinn Architecture Biennale Pavillion (2017) (

click here to see the project

) and a multi-family home in Wemmel, close to Brussels (2015).

▼场地中的模块元件与组装部件,elements and element assembly on the site

▼效果图,rendering

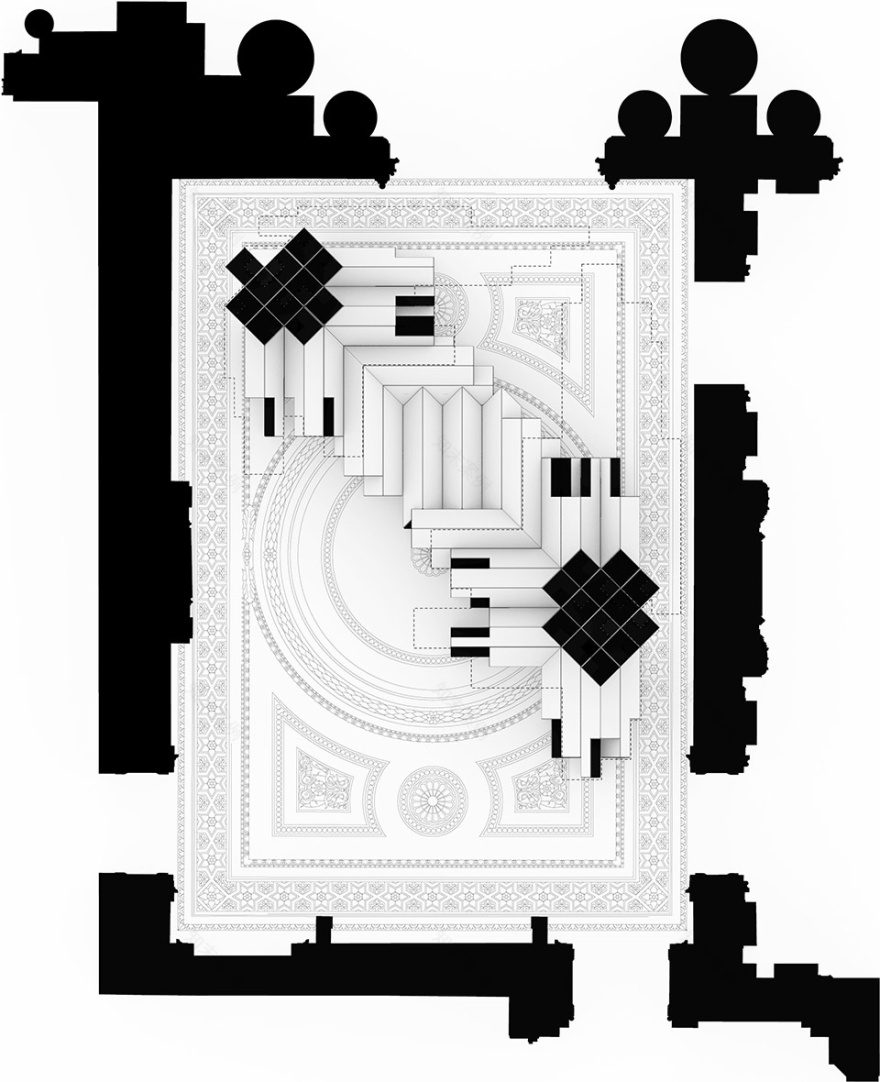

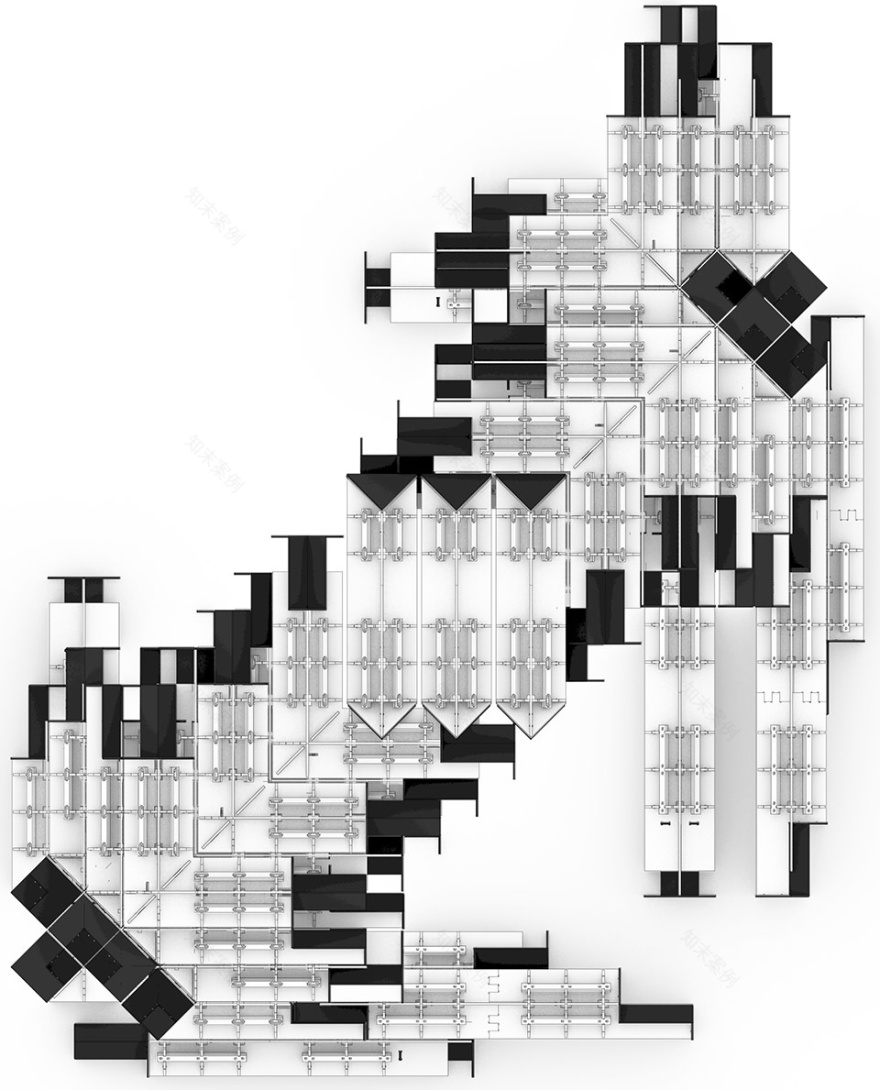

▼平面图,floor plan

▼天花板平面,reflected ceiling

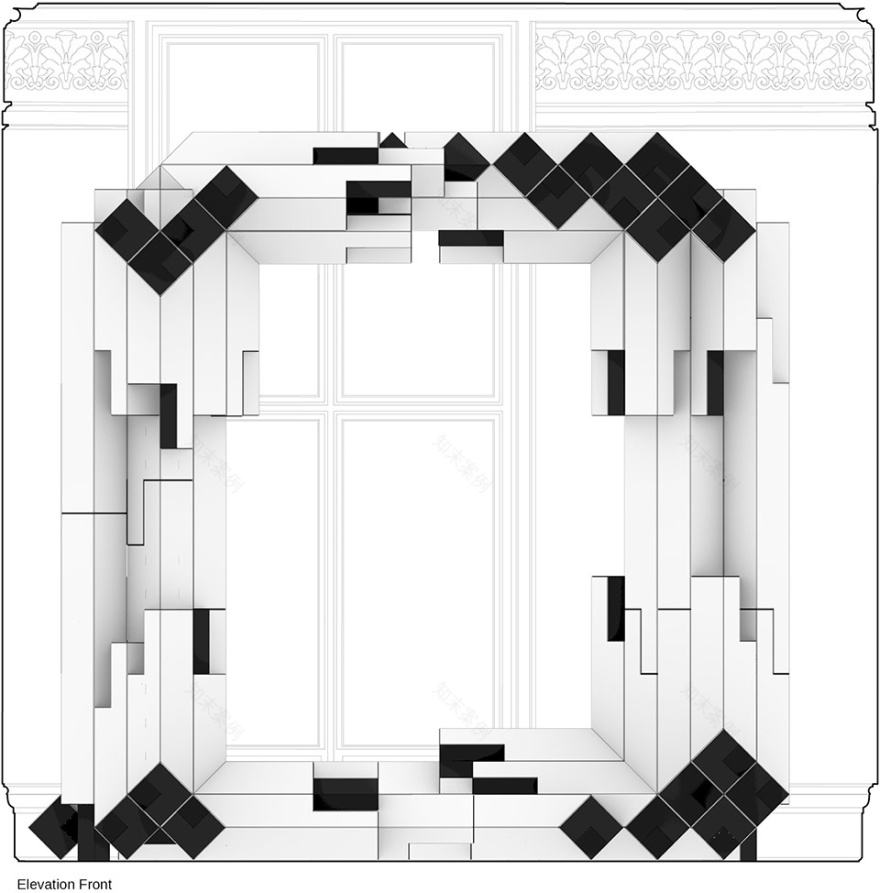

▼正立面,elevation front

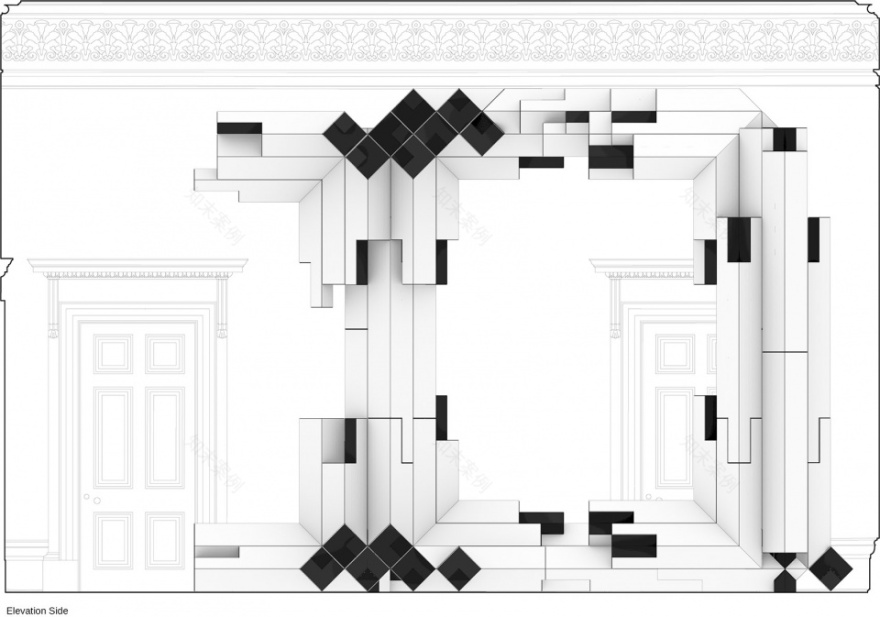

▼侧立面,elevation side

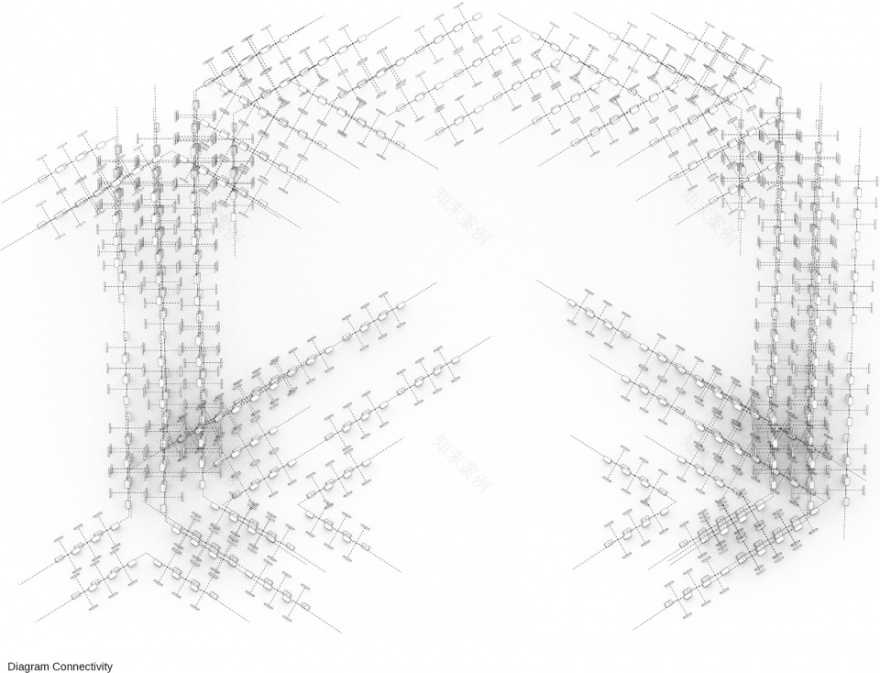

▼连接点图解,diagram connectivity

Project name: Real Virtuality

Design:

Gilles Retsin Architecture

Team: Gilles Retsin, Kevin Saey, Johan Wijesinghe

Website:

gilles@retsin.org

Design & Completion Year: 2019

Project location: London

Gross Built Area: 35m2

Clients: Royal Academy

Engineering:

Manja Van de Worp,YIP Structural Engineering London

Pre-Fabrication:

Kevin Saey, Johan Wijesinghe, Mario Medina, Rida Qurashi, Effie Douroudi, Manuel Montoro, Tanishk Saha, Athina Athiana, Eleana Georgousi, Akhmet Khakimov, Eirini Tsomokou, Evangelia Triantafylla, Vicente Sánchez Seoane, Ming Liu, Po-Fu Yang, Evgenia Krassakopoulou, Ning Zheng, Keshia Lim, Joana Calado Correia, Chuan Tian, Mengmeng Zhao, Pablo Maldonado, Gilles Willems, Nadia Souki, Shuting Guo, YenFen Huang, HungDa Chien, Charles Wu

On-Site Construction:

Isaie Bloch, Brecht Reynaert, Kevin Saey, Johan Wijesinghe

The Bartlett School of Architecture:

Design Computation Lab: Mollie Claypool, Manuel Jimenez, Gilles Retsin, Vicente Soler

Bartlett B-Made: Niamh Grace, David Shanks, Mads Peterson, Alex McCann, John Henshaw

Augmented Reality: Fologram

Photography: NAARO

With the support of MetsaWood.

Video:

ScanLAB Projects

and

Keiichi Matsuda

Video link:

客服

消息

收藏

下载

最近