查看完整案例

收藏

下载

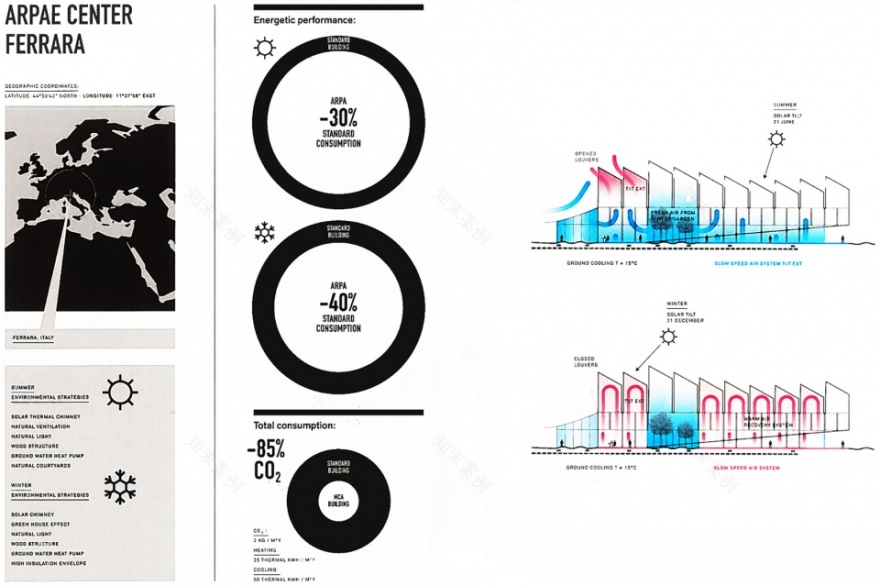

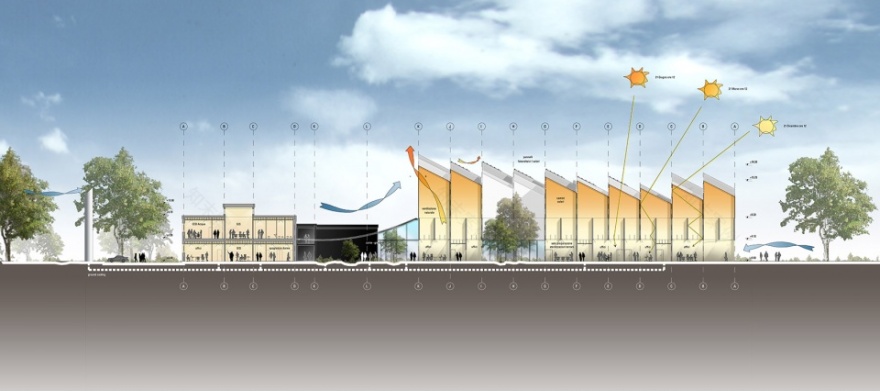

项目探索形式与性能之间的关系,使其成为意大利首座“主动式节能”和“被动式节能”相结合的可持续公共建筑。项目所在位置费拉拉的气候通常在两个极端之间波动:夏季炎热潮湿,冬季寒冷湿润,只有在春季,温度和湿度之间才会达到平衡。我之所以这样说,是因为可持续性的定义不仅是一个还有待解决的美学问题,而且还包括与环境,生物气候和人关系的同理心。屋顶由112个具有双重功能的“烟囱”组成:分配和控制阳光并改善自然通风。

▼能源局鸟瞰图,屋顶由112个具有双重功能的“烟囱”组成,bird-eye’s view of the project, the roofing consists in a series of 112 chimneys that have a twofold function

The project in Ferrara explores the relationship between form and performance, that makes it the first hybrid public building in Italy. We are just outside the city of Ferrara, whose climate oscillates between two extremes: hot and humid in the summer, cold and damp in winter. Only in spring do we have a normal relationship between temperature and humidity. I am pointing this out because the definition of sustainability— which still needs to be worked out—is not only concerned with aesthetics, but also relationships of empathy with places, climate, and people. The roofing consists in a series of 112 chimneys that have a twofold function: controlling light distribution, and enhancing natural ventilation.

▼概念草图,concept sketch

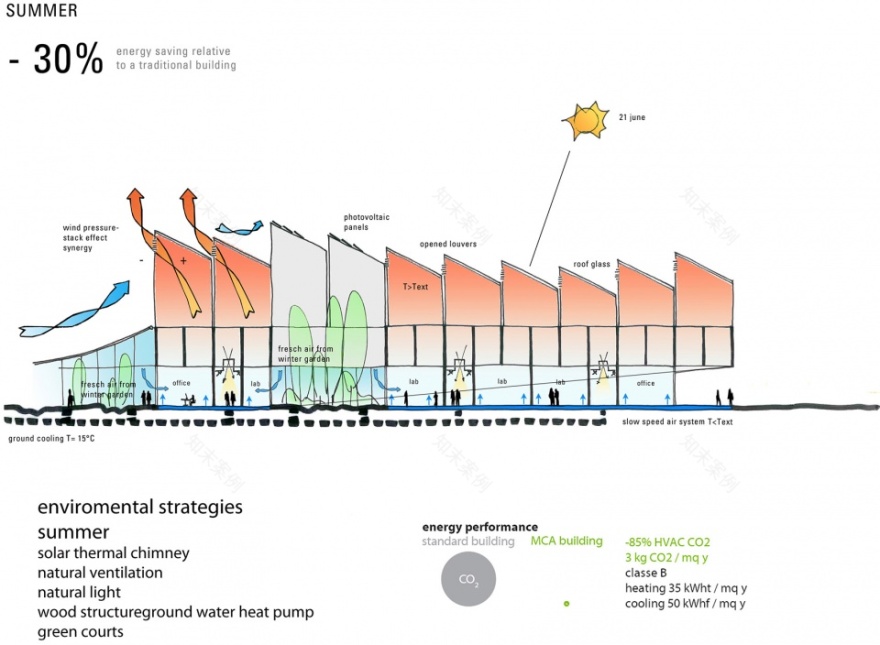

▼空间轴测图,the axon

夏季和冬季,烟囱的工作方式有所不同:在夏季,由于烟囱效应,热空气被排出,避免了热量分层,而在冬季,它们像温室一样发挥作用:积聚太阳能,并在建筑物内重新散发。所有这些都无需成本,也无需特别技术的投入。我想探索的就是这个想法:在建筑的分析和模拟上比仅技术投入更多,从而创建能源系统混合型的建筑。这代表了朝着生态时代迈进的建筑的真正变化,气候极端情况下带来的巨大环境挑战成为了创新发展的机遇。

▼冬季环境策略,the environmental strategies in winter

▼夏季环境策略,the environmental strategies in summer

The chimneys work differently in summer and in winter. In the summertime, the chimney effect expels air in the upper part of the building, thus avoiding the buildup of heat, whereas in winter, they work like greenhouses: accumulating solar heat that gets pumped back inside the building. This entire process is cost-free, and needs no technological add-ons. This is the idea I would like to explore: investing more in analysis and simulation rather than on technology alone, creating a hybrid building. This is what best represents the true change leading to a new, ecological age, that transforms environmental risks related to climate emergency to an opportunity of development.

▼项目外观,exterior view of the project

▼项目立面,the facade view of the project

该建筑完全由木材建成,采用现场组装。它围绕着一个内部庭院发展,该庭院还可以用作气候花园。吸收二氧化碳,控制和优化自然光,调节自然通风,有节制地使用技术,将注意力集中在空间质量和舒适度上:这是以一种可见的新形式和隐形的美观来定义可持续性的要素。

▼项目外观,建筑完全由木材建成,exterior view of the building that is entirely made of wood

▼项目外观,底层采用玻璃外墙,上层木表皮空间外挑,exterior view of the project with glazing facade on the ground floor, the upper levels with wood skin protrude

The building is entirely made of wood and constructed on site. It is built around an inner patio, which also functions as a climatic garden. Building with wood, controlling natural light and ventilation, using technology sparingly, and focusing on well being, comfort, and quality of space: these are the ingredients for defining sustainability as a new form of visible and invisible beauty. – Mario Cucinella

▼建筑及其内院,the building and its inner patio

▼建筑围绕着一个内部庭院发展,the is built around an inner patio

气候策略 | Climate Strategies

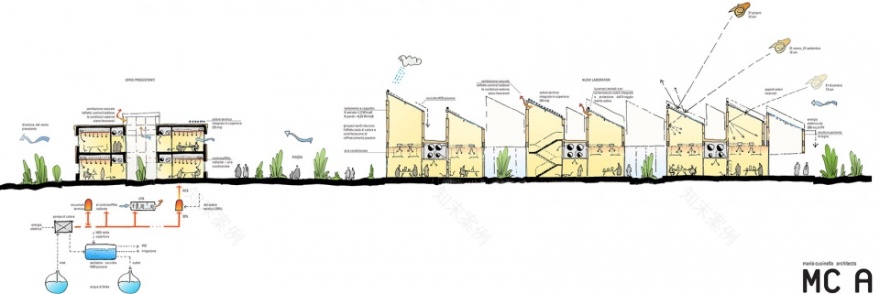

设计采用的策略使建筑成为生物气候过滤器,其目标是每年供暖和空调消耗均低于100 Kwh / m2 /年。这一低能耗标准的实施要归功于主动和被动生物气候策略以及技术系统的结合。被动策略包括自然通风,这要归功于烟囱和温度梯度产生的空气循环,从而增加了用户在夏季和夏季的热舒适度。内部庭院创建产生的微气候可以通过日光控制,使得植被和非矿物质表面都降低温度。此外,在立面和屋顶上形成开口,由于堆叠效果,可以产生更好地抽风和移动。所有这些都通过压力开关自动控制,因此屋顶起着至关重要的作用。

▼生物气候分析图,the biological climate diagram

The implemented strategies turn the building into a bioclimatic filter that aims at an annual consumption below 100 Kwh/m2 for both heating and cooling. This is possible thanks to the combination of active and passive bioclimatic strategies and technical systems. Passive strategies include natural ventilation, which is promoted thanks to air circulation generated by shafts and temperature gradients, thereby increasing thermal comfort during the summer and mid seasons. The creation of internal courtyards generates a microclimate that can lower the temperature through sunlight control, vegetation and non-mineral surfaces. Moreover, it creates openings in the façade and roof, allowing for better air extraction and movement thanks to the stack effect. All this is ensured by pressure switch-controlled automatic openings. This way, the roof plays a crucial role.

▼在立面和屋顶上形成开口,由于堆叠效果,可以产生更好地抽风和移动,creating openings in the façade and roof, allowing for better air extraction and movement thanks to the stack effect

▼内部庭院创建产生的微气候可以通过日光控制,the creation of internal courtyards generates a microclimate that can lower the temperature through sunlight control

屋顶的一个最重要的功能是在适当地定向后,它将成为自然光导管,在夏季变成热空气提取器,在冬季变成真正的太阳能收集器。将大约300平方米的光伏面板放置在一些具有最佳朝向的屋顶烟囱上,最大程度地提高太阳能利用效率。此外,在现有建筑物的屋顶上增加了太阳能电池板,用于生活热水的生产。同时可根据需要校准屋顶和立面上的不透明和透明部分。这种类型的建筑有助于尽可能多地利用屋顶的自然光来满足活动的需求。

Suitably oriented, it becomes a zenithal natural light shaft, a hot air extractor during the summer, and a solar capturing surface (a true solar collector) during the winter. About 300 m2 of photovoltaic panels are placed on some of the shafts on the roof, which are optimally oriented to maximize solar energy efficiency. Moreover, solar panels have been added to the roof of the existing building for domestic hot water production. This type of architecture helps exploit zenithal natural lighting as much as possible – especially important to meet the requirements of the activities that the building will house – by calibrating opaque and transparent parts both on the roof and the façade according to needs.

▼在具有最佳朝向的屋顶烟囱上放置光伏面板,最大程度地提高太阳能利用效率,placing photovoltaic panels on some of the shafts on the roof, which are optimally oriented to maximize solar energy efficiency

▼从室内看屋顶,viewing the roof from inside

技术体系与结构 | Technical systems and structures

整个建筑从外观开始就旨在最大程度地减少对技术系统的使用。在任何情况下,其运行所需的大部分资源都来自可再生能源。两个多用途地下水基装置可产生专用的必要热能和冷却能,该装置可在一年中的任何时候利用光伏系统产生的电能同时产生热水和冷水,从而消除了向大气的污染排放。

生活热水主要由屋顶的太阳能电池板产生,部分来源于中央供暖系统。控制系统有助于最大程度地利用太阳能。当没有太阳能时必不可少的二次加热可满足任何其他空间的加热要求。所有办公室,会议室和档案馆均配有空调和水性空调系统。在办公室区域,通过配备有高效回收系统的空气处理 单元确保空气更新,该系统可以在室外温度允许时以自然冷却模式运行。同时实验室配备了可变风量通风系统(VAV),以补偿运行中的实验室排风罩抽取的空气,使该实验室相对于任何地方的周围环境保持低压操作。

此外,一个单独的雨水收集和冷凝水回用系统为提供卫生间用水。建筑物的承重结构使用符合EN 14080和DIN 1052标准的云杉木板胶合层,直角矩形截面的结构元件制成。结构非常简单,由支撑上层竖井甲板的立柱和横梁框架组成。横截面为60×20厘米的主梁沿着建筑物的较短侧布置在两条轨道上。 6×3 m结构框架上的柱子由云杉胶合层制成,横截面为29×29 cm,平均高度为4.5 m。立柱直接支撑在基础上,基础形成倒置的梁格。根据EN 14080标准的规定,用于接线柱的云杉胶合层属于强度等级GL32或GL36。金属制品对结构节点具有功能,并已适当地防腐蚀。加强和支撑系统,以及氯丁橡胶轴承垫也已安装到位。支配建筑物三侧的竖井在南侧悬垂六米,在东西两侧较长的悬垂三轴。悬臂由横梁和立柱框架以及竖井甲板内的钢杆系统支撑。

▼能源消耗分析,the energy consumption analysis

The whole building – starting from its shape – is designed to minimize the use of technical systems. In any case, most of the energy required for their operation comes from renewable sources. The necessary thermal and cooling energy is produced for exclusive use thanks to two multipurpose groundwater-based units, which can simultaneously produce hot and chilled water during any time of the year, using the electricity produced by the photovoltaic system, thereby eliminating emissions into the atmosphere.

Domestic hot water is produced by the solar panels on the roof and partly by the central heating system. A control system helps exploit solar energy to the fullest. Secondary heating – essential when solar energy is not available – meets any additional space heating requirement. All offices, meeting rooms, and archives are equipped with an air- and water-based air conditioning system. In the offices, primary air is ensured by air handling units provided with a high-efficiency recovery system that can operate in free cooling mode when the outdoor temperature allows. The laboratory is equipped with a variable air volume (VAV) ventilation system to compensate for the air extracted by the laboratory hoods in operation, keeping the room under negative pressure compared to the surrounding areas in any operating mode.

Moreover, a separate rainwater harvesting and condensate reuse system provides water for toilet flushing. The load-bearing structure of the building is made of glulam and consists of straight rectangular cross-section structural elements made using spruce wood boards in accordance with the EN 14080 and DIN 1052 standards. The structure is quite simple and consists of a post and beam frame supporting the overlying shaft deck. The main beams with a 60×20 cm cross-section are arranged on two rails along the shorter side of the building. The posts on the 6×3 m structural framework are made of spruce glulam and have a 29×29 cm cross-section and an average height of 4.5 m. The posts bear directly on the foundation, which forms an inverted beam grid. The spruce glulam used for the posts falls within strength class GL32 or GL36, as stipulated in the EN 14080 standard. The metalwork is functional to the structural nodes and suitably protected against corrosion. Stiffening and bracing systems, as well as neoprene bearing pads, are also in place. The shafts that dominate three sides of the building overhang six meters on the southern side and three on the longer eastern and western sides. The overhangs are supported by the beam and post frame and a system of steel rods within the shaft deck.

▼建筑室内,建筑结构由支撑上层竖井甲板的立柱和横梁框架组成,interior view, the structure consists of a post and beam frame supporting the overlying shaft deck

木材 | Wood

建筑完全由木材制成,并具有现场干式装配系统,该系统考虑到从施工阶段开始就减少了用水量。此外,干式装配系统有助于在整个建筑物的使用寿命中进行维护和元素更换。从形式角度来看,木材可以使建筑物完美地融入到波河流域周围植被丰富的景观中。除了云杉的胶合层结构外,还有用于建造竖井的甲板,该甲板由木钉和托梁框架组成。钢元素将所有木制元素连接到钢筋混凝土基础上。甲板内部已装满双层纤维板(10cm 160kg / mc,+ 10cm 270Kg / mc),总厚度为200 mm。通过两侧的OSB面板固定在一起,不仅方便了运输到施工现场,还可以用作支撑结构。在竖井内部的OSB面板上固定有3×3 m垂直立式听板框架,然后将22毫米厚的3-S云杉胶合板固定到框架上,并用白色染料浸渍,形成最终的内饰面。在外部,水平3×3 m腰线的框架固定在OSB面板上。然后将具有不同厚度的交错的垂直条沿水平方向固定框架,从而增加立面的移动性。

▼木材可以使建筑物完美地融入到波河流域周围植被丰富的景观中,wood allows the building to integrate perfectly into the surrounding vegetation-rich landscape typical of the Po Valley area

▼树林中的建筑,the building in the natural forest

The new building is entirely made of wood with an on-site dry construction system, which means that reducing water consumption starts in the construction site. Moreover, the dry assembly system facilitates maintenance and the replacement of elements throughout the building’s lifespan. From a formal point of view, wood allows the building to integrate perfectly into the surrounding vegetation-rich landscape typical of the Po Valley area. In addition to the spruce glulam structure, there is the deck on which the shafts are built, which consists of a timber stud and joist frame. Steel elements connect all wooden elements and these to the reinforced concrete foundation. The inside of the deck is filledwith a double fiberboard panel (10cm 160kg/mc, + 10cm 270Kg/ mc) with an overall thickness of 200 mm. This “package” is held together by OSB panels on both sides, which not only facilitate transport to the construction site but also serve as bracing structures. A framework of vertical 3×3 m listels is fixed to the OSB panels on the inside of the shafts. 3-S spruce plywood panels are then fastened to the framework. These plywood panels, which are 22 mm thick and are impregnated with white dye, form the final internal finish. On the outside, a framework of horizontal 3×3 m listels is fastened to the OSB panels. Staggered vertical listels with varying thickness are then fixed along the horizontal direction of the framework, thereby adding movement to the façade.

▼建筑外立面,将具有不同厚度的交错的垂直条沿水平方向固定框架,增加立面的移动性,exterior facade, staggered vertical listels with varying thickness are then fixed along the horizontal direction of the framework, adding movement to the façade

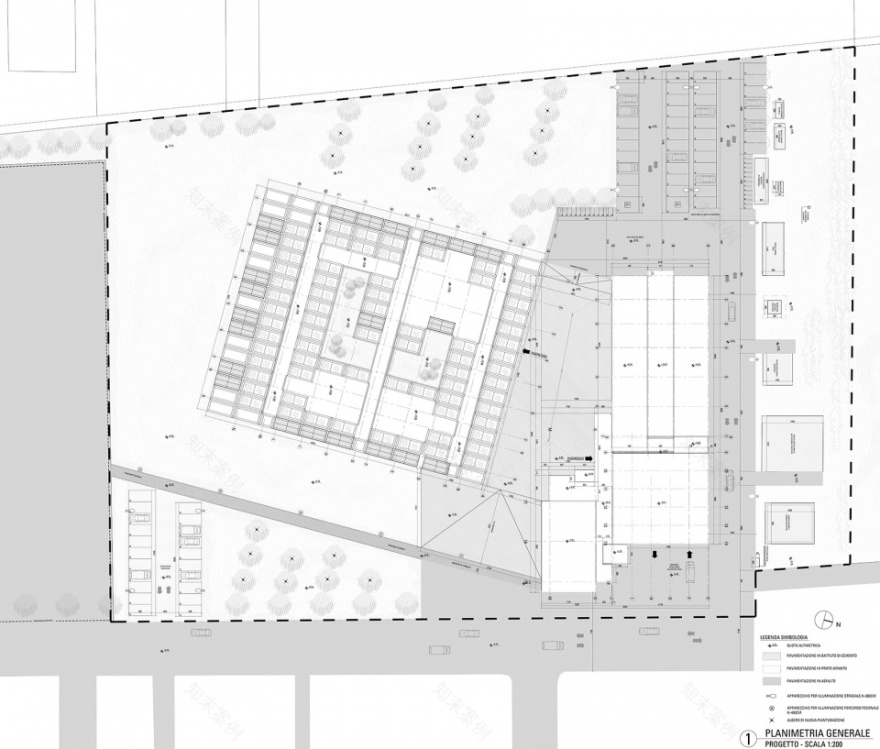

▼总平面图,site plan

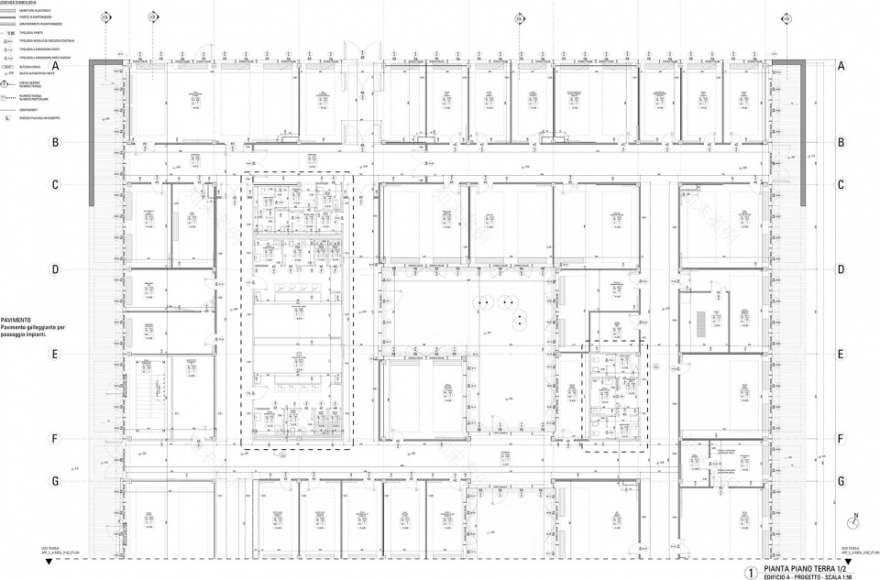

▼首层平面图,first floor plan

▼北立面图,north elevation

▼西立面图,west elevation

▼AA剖面图,AA section

▼BB剖面图,BB section

位置:意大利,费拉拉

类型:国际招标项目中标

年份:2006-2018

客户:费拉拉环境能源局

面积:5,000 平方米

项目:MC A建筑设计

管理:Giulia Floriani, Eugenio Roncacci

团队:Mario Cucinella, Michele Olivieri, Giulio Desiderio, Chiara Tomassi, Francesco Barone, Caterina Maciocco, Antonella Maggiore, Giulio Pisciotti, Luca Stramigioli, Alessio Rocco, Debora Venturi

模型制作:Natalino Roveri, Yuri Costantini, Andrea Genovesi

结构工程:Tecnopolis S.p.A.

木结构:SWS Engineering

生物气候分析:TIFS Ingegneria

电气工程:Tecnopolis S.p.A.

建设单位:Montelaghi S.p.A.

供应商:Novello Ambiente S.p.A. (wood); Base S.p.A. (fixtures)

3D渲染:Engram studio

摄像:Moreno Maggi

Location: Ferrara, Italy

Type: International competition – winning project

Year: 2006-2018

Client: Arpa Ferrara

Surface area: 5,000 sqm

Project: Mario Cucinella Architects

Management: Giulia Floriani, Eugenio Roncacci

Team: Mario Cucinella, Michele Olivieri, Giulio Desiderio, Chiara Tomassi, Francesco Barone, Caterina Maciocco, Antonella Maggiore, Giulio Pisciotti, Luca Stramigioli, Alessio Rocco, Debora Venturi

Model makers: Natalino Roveri, Yuri Costantini, Andrea Genovesi

Structural engineering: Tecnopolis S.p.A.

Wooden structures: SWS Engineering

Bioclimatic analysis: TIFS Ingegneria

Electrical engineering: Tecnopolis S.p.A.

Construction company: Montelaghi S.p.A.

Suppliers: Novello Ambiente S.p.A. (wood); Base S.p.A. (fixtures)

3D Rendering: Engram studio

Photos: Moreno Maggi

客服

消息

收藏

下载

最近